As an innovation leader in the field of new materials, Dongguan No. 9 Cotton Products Co., Ltd. has officially launched bioporous composite fiber cotton —a strategic alternative material with the core advantages of " zero lint, no residue, and high performance ." It aims to provide companies in electronic atomization, medical filter materials, and other industries with a full-chain upgrade solution from materials to processes, helping the industry break through the dual barriers of technology and cost.

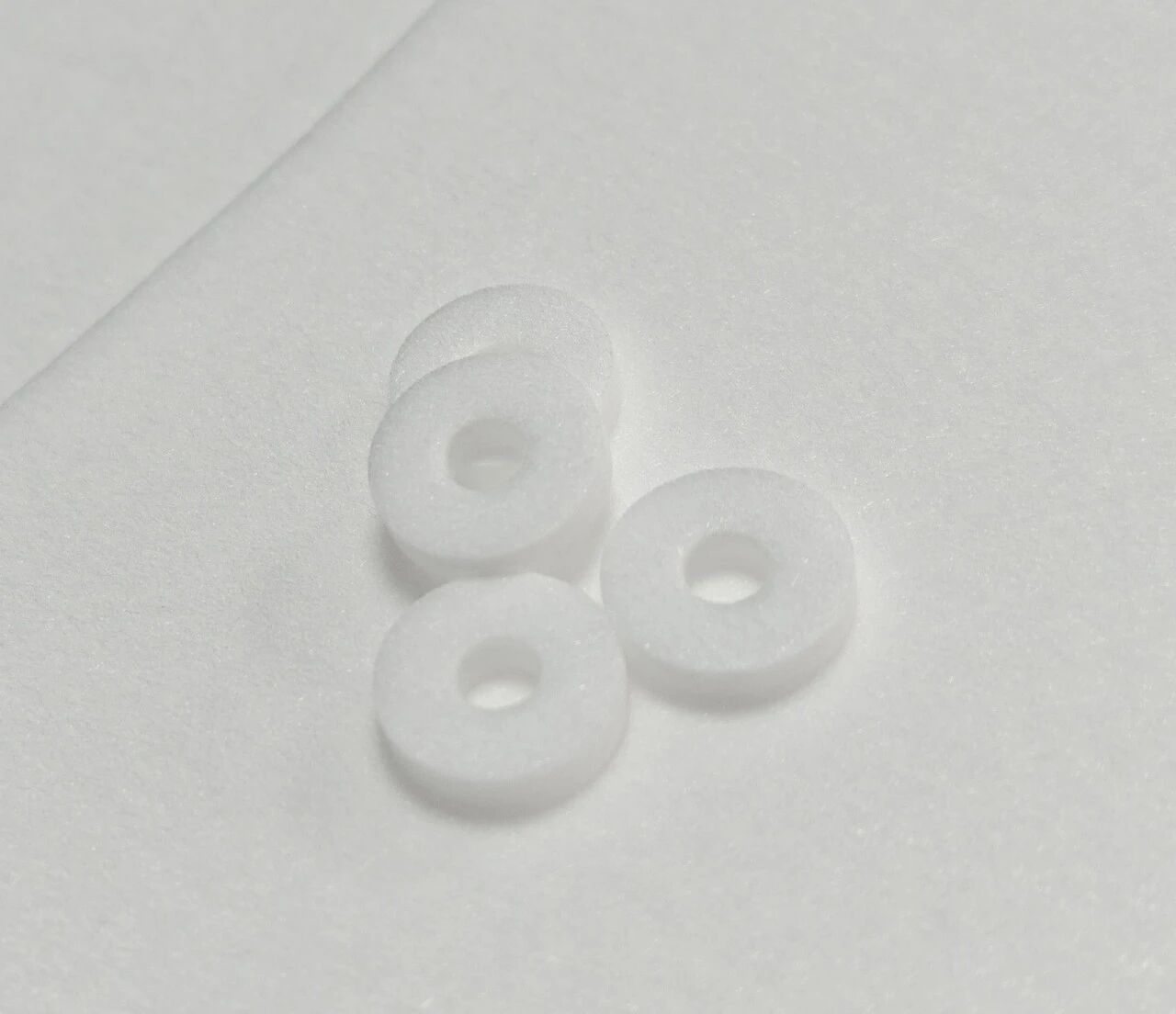

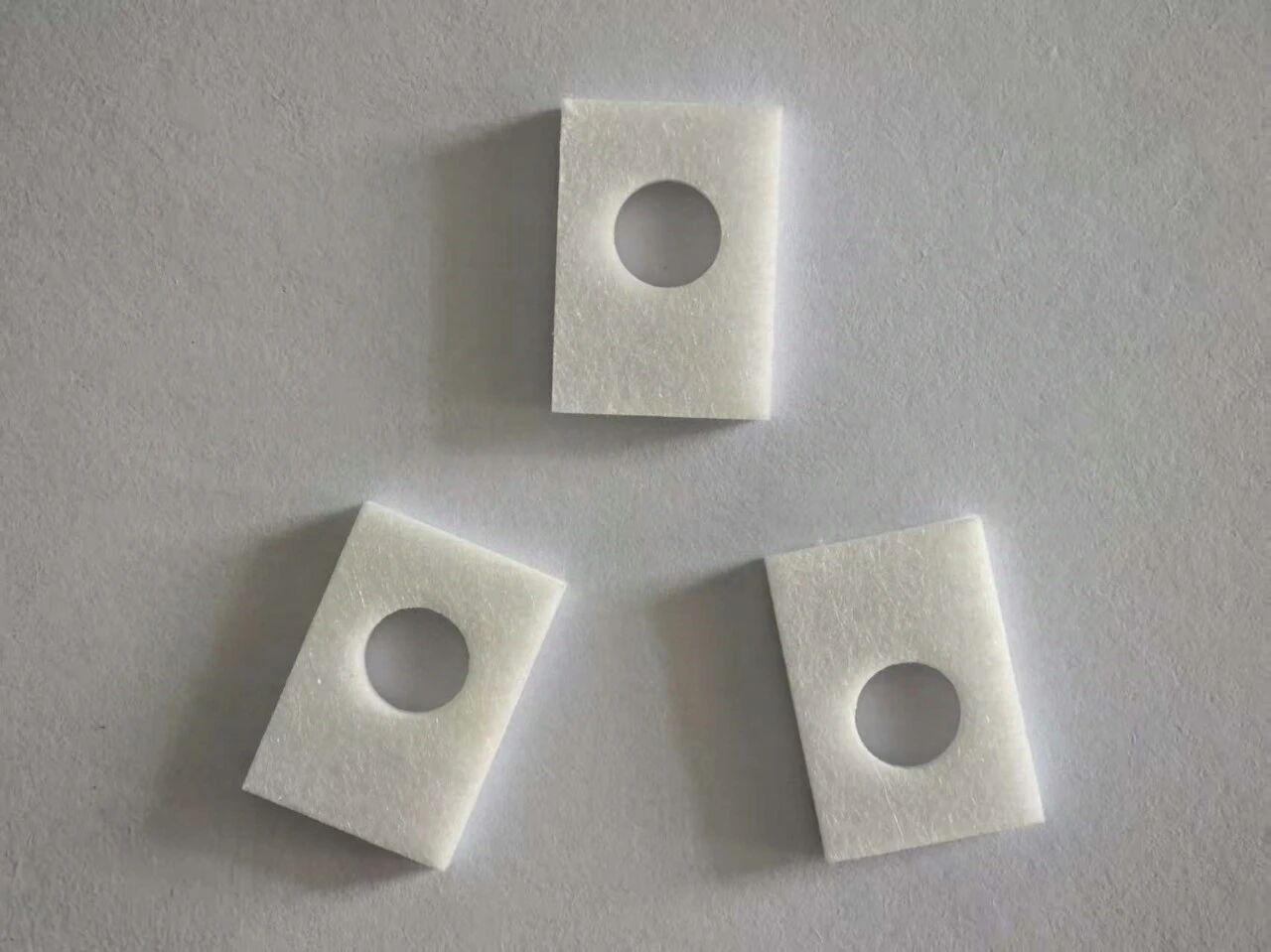

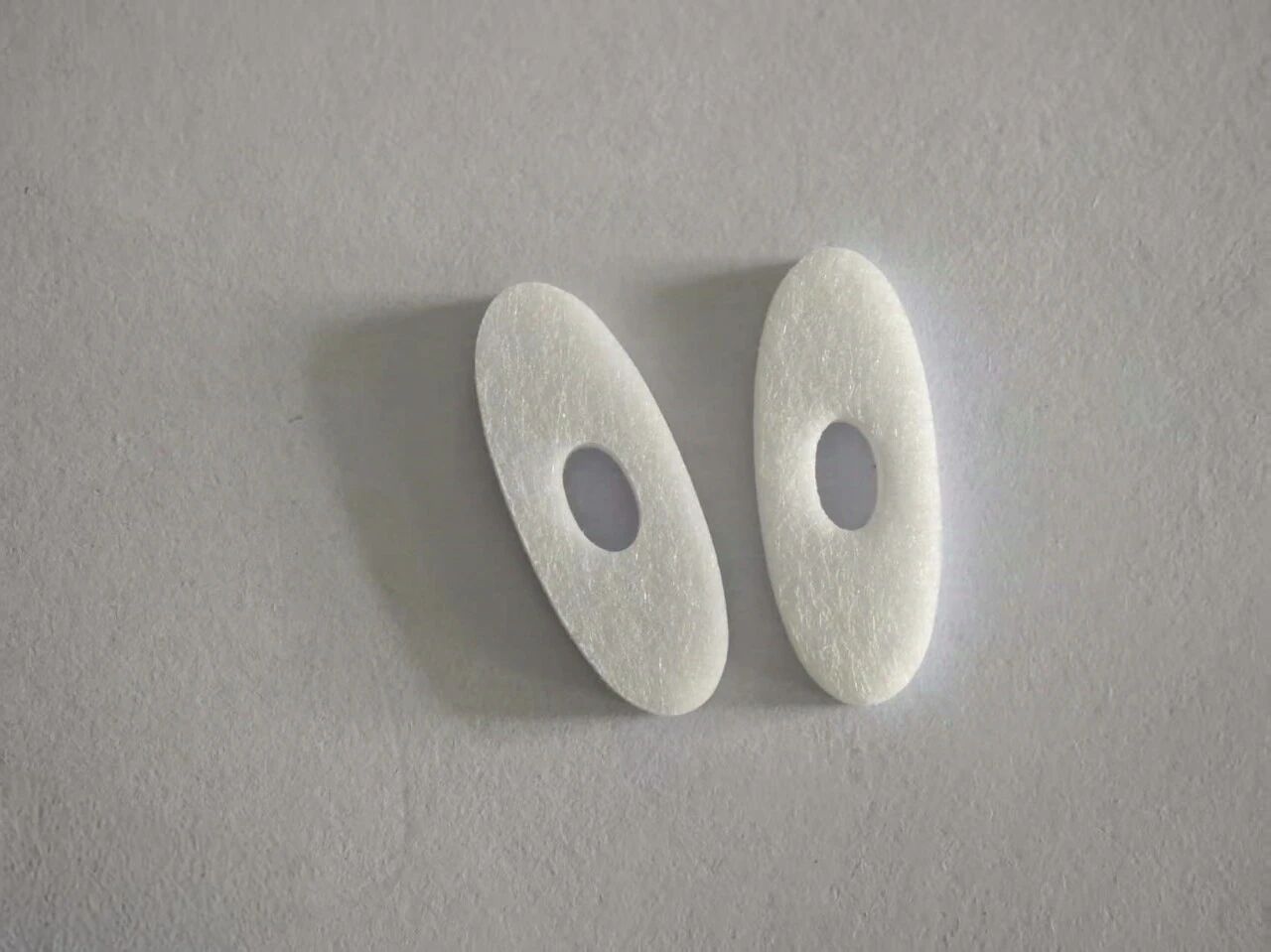

Positioning: A new lint-free composite material that can replace traditional polymers.

Advantages and selling points: Dust-free and lint-free, easy die-cutting, smooth and flat surface, high performance, self-developed and self-produced, low cost.

Needle-punched nonwoven fabrics require shaping processes such as needle punching during production. During processing, burrs can easily appear on the cut surface, and some fibers can easily fall off , leaving residues that accumulate and cause contamination . In applications within the electronic atomization industry, this can result in the inhalation of these fiber lint particles, potentially impacting human health.

Traditional polymer fibers cause pollution due to lint buildup , while special fibers are hard, difficult to die-cut, have low production volume and thickness limitations , and composite fiberboard is expensive .

1. The first challenge is addressing material residue , aiming to make the materials cleaner, more environmentally friendly, and safer to use;

2. Secondly, it breaks through thickness limitations to adapt to more orientations;

3. Next, optimize the production process to achieve simultaneous improvement in both quality and quantity .

First, the traditional needle punching process is abandoned, and a one-time molding technology is adopted to avoid unstable fiber connection and the generation of flying debris during needle punching.

The raw material uses bio -PLA/PP+PE core-sheath composite fiber , which not only has a smooth surface but also a uniform core-sheath structure, good wear resistance and bending fatigue resistance.

The unique bonding method stabilizes the three-dimensional structure, and the gaps in the space can absorb and store more than 8 times its own weight in liquid , and firmly lock in every drop of liquid. The interconnected gaps between the fibers promote the rapid transfer and uniform dispersion of liquid, achieving a unique layered identification method.

The surface is smooth and glossy , with tiny pores inside the material to store and absorb liquids. It is smooth and leaves no residue or lint. Rapid conduction between fibers achieves a double absorption effect, distributing liquid evenly without accumulation . The material's high hardness provides support, and the clean cuts are free of tangled fibers, making it suitable for unique applications. It offers excellent thermal insulation and dustproofing , strong chemical resistance , and is not prone to mold or insect infestation, making it easy to store.

Application areas: Mainly used in electronic atomizer condenser cotton, mouthpiece cotton, e-liquid absorbent cotton for e-liquid cartridges, medical filter plates , etc.

The benefits of lint-free products: Eliminating surface burrs, preventing fiber shedding, providing a more comfortable user experience, reducing usage risks, making products safer, and enhancing brand influence.

Customer value: For consumers, the core value of burr-free oil-absorbing cotton is " safer, purer, and more worry-free " —solving health hazards, taste imperfections, and operational inconveniences during use.

For brands: " Upgrading the details of the user experience " enhances product competitiveness, reduces operating costs, and ultimately achieves a dual increase in user retention and market reputation . Self-developed and self-produced products, optimized processes, and point-to-point service save companies significant time and procurement costs.

Both point to the same goal: the burr-free design allows e-cigarettes to advance from " usable " to " easy to use and safe to use , " aligning with the industry 's development trend from " extensive growth " to " refined experience . "

Dongguan No. 9 Cotton Products Co., Ltd.

Contact Person:

Mr. Cao: 13760129982

Mr. Wu: 15986727788