Analog silicon microphones vs. digital silicon microphones?Solving the challenges of acoustic sensor selection

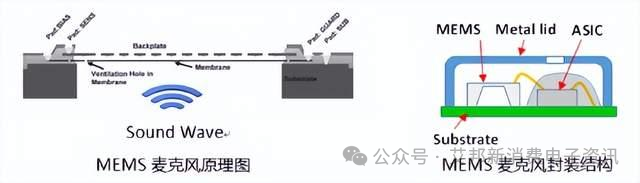

MEMS Mic

Digital microphone

Signal output: Digital signals are output using PDM (Pulse Density Modulation) or I2S (Integrated Audio Bus) protocols, which can communicate directly with the processor, reducing the analog-to-digital conversion stage.

Anti-interference: Built-in ADC (Analog-to-Digital Converter) provides excellent electromagnetic compatibility, making it suitable for high-RF interference scenarios (such as mobile phones and smart speakers).

Integration: Supports simultaneous sampling of multiple microphone arrays, suitable for complex algorithms such as beamforming and noise cancellation.

Power consumption: Typically slightly higher than analog microphones, but high-end models are optimized for low power consumption through design.

Analog microphone

Signal output: Directly outputs analog voltage signals, which simplifies circuit design and reduces costs when used for direct amplification applications.

Compatibility: Adapts to traditional audio interfaces, suitable for scenarios with low requirements for signal links (such as low-end headphones and industrial sensors).

Flexibility: Supports wide voltage supply, suitable for battery-powered devices.

Size and cost: Smaller package size (e.g., 2.75×1.85×0.95 mm), and unit price is usually lower than digital microphones.

Scenarios where digital microphones are preferred

High-end consumer electronics: devices such as smartphones and TWS earphones that require high signal-to-noise ratio (>60 dB) and resistance to radio frequency interference.

Industrial and automotive environments: In complex electromagnetic environments (such as factories and automotive electronics), the anti-interference capability of digital signals can ensure the stability of voice commands.

AIoT devices: Smart home terminals that require local voice processing (such as voice control modules), with digital interfaces to facilitate direct interaction with AI chips.

Scenarios that prioritize analog microphones

Cost-sensitive equipment: For categories with strict cost control, such as low-end headphones and toys, simulation solutions can reduce BOM costs.

Simple voice acquisition: Scenarios that do not require complex algorithms (such as conference recorders and security monitoring) simplify the design of analog signal links.

Miniaturized devices: In ultra-small wearable devices, the miniaturized packaging of analog microphones is easier to integrate.

As a leading enterprise in the domestic MEMS sensor field, Huaxinbang Technology has broken through technical barriers through independent innovation. Its MEMS acoustic sensors have reached the international advanced level in key indicators such as signal-to-noise ratio and sensitivity control.

With the official commissioning of Hainan Huaxin Intelligent Manufacturing's 30KK monthly capacity packaging line, a complete domestic supply chain from chip design to packaging and testing has been established. This not only ensures a stable and controllable delivery cycle but also significantly optimizes costs through large-scale production, providing global customers with cost-effective acoustic solutions and accelerating the replacement of domestic MEMS microphones in the high-end market.

MP421A: Omnidirectional pickup, strong anti-interference (PSRR 70 dB), suitable for mobile communication and smart home, passed thermal shock test from -40℃ to 125℃, ensuring industrial-grade reliability.

MP381A: Wide voltage compatibility (1.5–3.6V), low power consumption (typical 120 μA), designed for consumer electronics and industrial applications, supports 5 reflow soldering cycles, and is suitable for automated production.

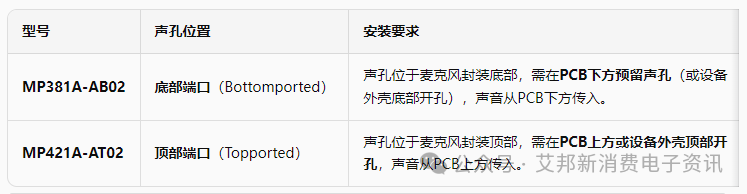

Matching equipment structure and sound pickup requirements

Devices with openings on the bottom or sides: such as the bottom of laptops, smart speaker docks, desktop devices, etc., where the PCB can directly contact the external sound field without needing to avoid additional components.

Hidden sound pickup design: The sound hole can be integrated into the bottom of the device or a non-visible surface to avoid affecting the appearance (such as smart home control panels).

It needs to be mounted close to the back of the PCB: When there is no metal shield or obstruction under the microphone and it is necessary to shorten the sound propagation path (such as small sensor modules).

Scenarios where MP421A is preferred

The device has openings on the top or front: such as the microphone on the top of a mobile phone, TWS earbuds, and the earcups of headphones, etc., and the sound needs to enter directly from the front/top of the device (close to the user's mouth or the direction of the sound source).

No components obstructing the top of the PCB: The top of the microphone must be exposed to the air and there should be no tall components (such as capacitors or connectors) blocking the sound hole (such as the top of the dial of a wearable device).

Small gap between the casing and the PCB: When the device thickness is limited, the casing can be directly attached to the top of the PCB, and sound can be picked up through the openings in the casing (such as ultra-thin tablets and smartwatches).

Official website | Hotchip.com.cn

Business cooperation | 18824277771

Address | Minzhi Subdistrict, Longhua District, Shenzhen

North Station Community Hongrongyuan North Station Center Building B

来源:华芯邦