E-cigarettes usually consist of batteries, atomizers and e-liquid, which can avoid harmful substances produced when traditional cigarettes are burned. Due to their smoke-free, tar-free and low-odor characteristics, e-cigarettes are considered a harm-reduced alternative to traditional smoking.

1. Shell: The shell of an e-cigarette is usually made of durable plastic materials to protect the internal electronic components. Common materials include ABS (acrylonitrile butadiene styrene) and PC (polycarbonate), which have good impact resistance, heat resistance, and chemical resistance.

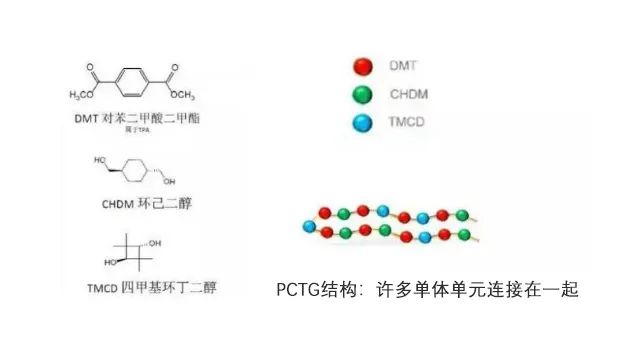

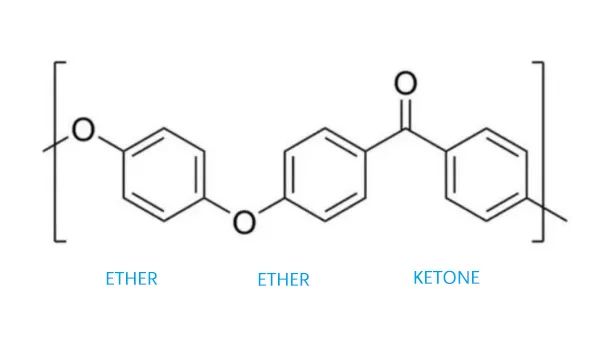

2. Mouthpiece: The mouthpiece is the part of the e-cigarette that contacts the user, and is usually made of food-grade plastic materials, such as PCTG (copolyester) or PEEK (polyetheretherketone). These materials are resistant to high temperatures, corrosion, and are non-toxic, and can meet the safety requirements for oral contact.

3. Oil tanks and reservoirs: These parts are used to store e-liquid and are usually made of transparent and chemically resistant plastics such as PCTG or PEEK. This allows users to easily check the remaining amount of e-liquid.

4. Internal components: Some small components inside the electronic cigarette may also be made of plastic, such as the battery compartment, fixing bracket, etc. The materials used for internal plastic parts usually emphasize high temperature resistance and chemical corrosion resistance to ensure the safety and durability of the device.

The selection of these plastic parts mainly considers their chemical stability, high temperature resistance, non-toxicity and mechanical strength to ensure the overall performance and safety of electronic cigarettes. Among them, the types of plastics used arePCTG、PPSU、PP、PC、PEEK、透明尼龙等。

一、PCTG

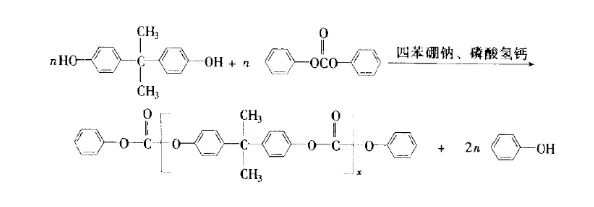

PCTG was previously used in cosmetic packaging and plastic water cups due to its glass-like transparency and density, no bisphenol A, excellent food hygiene and flame retardancy, etc. It is currently used in most e-cigarette oil tanks, cigarette holders, cigarette rod shells, etc., and the demand is huge.

PPSU is a new type of non-crystalline thermoplastic engineering plastics, which is light, high-strength, good odor at high temperatures, does not contain bisphenol A, will not denature even after repeated heating, has good sterilizability, and can be in contact with water for a long time. And one of its typical applications is baby bottles, so it is also called "baby bottle material".

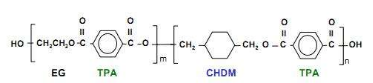

Polyphenylene sulfone PPSU is synthesized from 4,4'-biphenol and 4,4'-dichlorodiphenyl sulfone through salt formation, polycondensation and other steps. The molecular structure is as follows:

PPSU树脂的结构式

图 IQOS上盖外壳采用PPSU改性材料(来源网络)

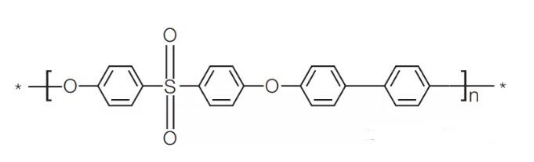

三、PEEK

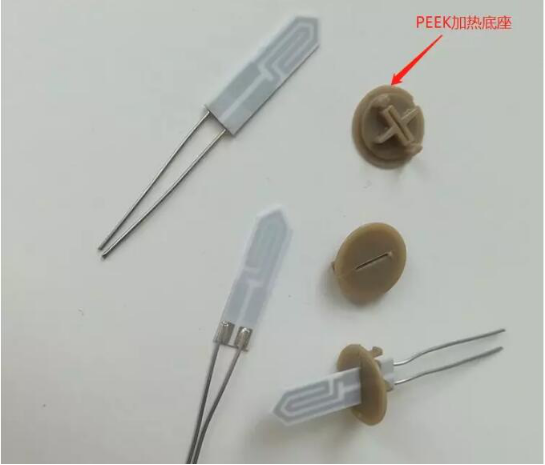

PEEK is a thermoplastic special engineering plastic. Due to its good mechanical properties, high melting point, biocompatibility and non-toxicity, it meets FDA certification. Polyetheretherketone (PEEK) refers to a linear aromatic semi-crystalline polymer whose main chain consists of aromatic, ketone and ether bonds. It belongs to the polymer family of "aromatic polyketone".

图 电子烟周边PEEK加热配件

四、Transparent nylon

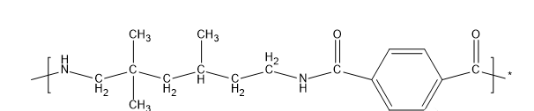

It has excellent transparency (even higher than PC and close to PMMA), and is superior to general transparent polymer materials (such as PS, PC, PMMA, etc.) in terms of environmental stress cracking resistance, oil solvent resistance, scratch resistance, and wear resistance. Common transparent nylon types include PA MACM12, PA 12/MACMI, PA 6I/X, etc.

PA12 结构式

五、PP

Polypropylene is a semi-crystalline thermoplastic. It has high impact resistance, strong mechanical properties, and is resistant to corrosion by many organic solvents and acids and alkalis. With good performance, PP is the only plastic that can be put into a microwave oven. It has high strength and flexural resistance (50,000 times) and will not break at -20°C.

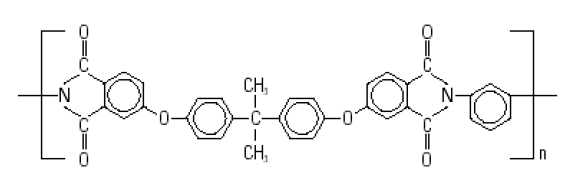

六、PEI

PEI, scientific name of polyetherimide, is a non-crystalline thermoplastic with high mechanical strength and rigidity. It has very high creep resistance in a wide temperature range and long-term high working temperature. In addition, it has very good hydrolysis resistance and dimensional stability. The disadvantage is that the price is slightly higher.

PEI 结构式

Polyoxymethylene POM, commonly known as "super steel" or "saigang", has a smooth, shiny, hard and dense material with a light yellow or white appearance. It is an engineering plastic with excellent comprehensive performance after polyamide PI and one of the five general-purpose engineering plastics.

POM has good mechanical properties and rigidity, and can be combined with metal materials; POM has excellent fatigue resistance and creep resistance; good wear resistance, self-lubrication and friction resistance; it is currently widely used in electronic cigarette mouthpiece materials.

八、PC

PC material is transparent, has good impact resistance and good dimensional stability, and is used in electronic cigarette atomizers and mouthpieces. It is understood that the transparent mouthpiece of E-hose electronic hookah uses a PC plastic mouthpiece, and some electronic cigarette brands also use PC material for the shell of the cigarette cartridge.

原文始发于微信公众号(艾邦新消费电子资讯):8 common plastics in electronic cigarette structural parts

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.