In the electronic vaporizer market, a market teeming with both opportunities and challenges, HCD has become a global leader in atomizer core manufacturing with its superior technical expertise, efficient service system, and reasonable pricing strategies. Its professional standing stems from its unwavering commitment to technological innovation, strict control of product quality, and in-depth understanding of customer needs.

HCD has been focusing on the research and development and production of atomizer cores for 16 years, accumulating a deep technical foundation and innovative experience. Leveraging leading atomization technology, the company continuously drives product iteration and upgrades, earning over 400 patents, demonstrating its strong technical capabilities. In particular, HCD is at the forefront of the industry in the development of ceramic and cotton atomizer cores.

For its ceramic atomizer core, HCD uses food-grade ceramic materials that are lead-free and mercury-free, and introduces a dual-grid, graded heating mechanism to achieve efficient, precisely controlled atomizer liquid conduction. This innovation not only significantly increases vapor volume but also ensures even heat distribution and efficient transfer, providing users with a purer, smoother atomization experience.

In the field of cotton atomizer wicks,HCD overturned the traditional simple method of burning cotton and pioneered the COTTONX future cotton wick. Its two structural solutions, "wrapped cotton" and "flying cotton," completely changed the inherent impression of cotton wicks as prone to sticking. The subsequent COTTONX Plus double-mesh cotton wick has withstood the rigorous test of the market and become one of its core competitive advantages.

Quality control: ensuring customer satisfaction

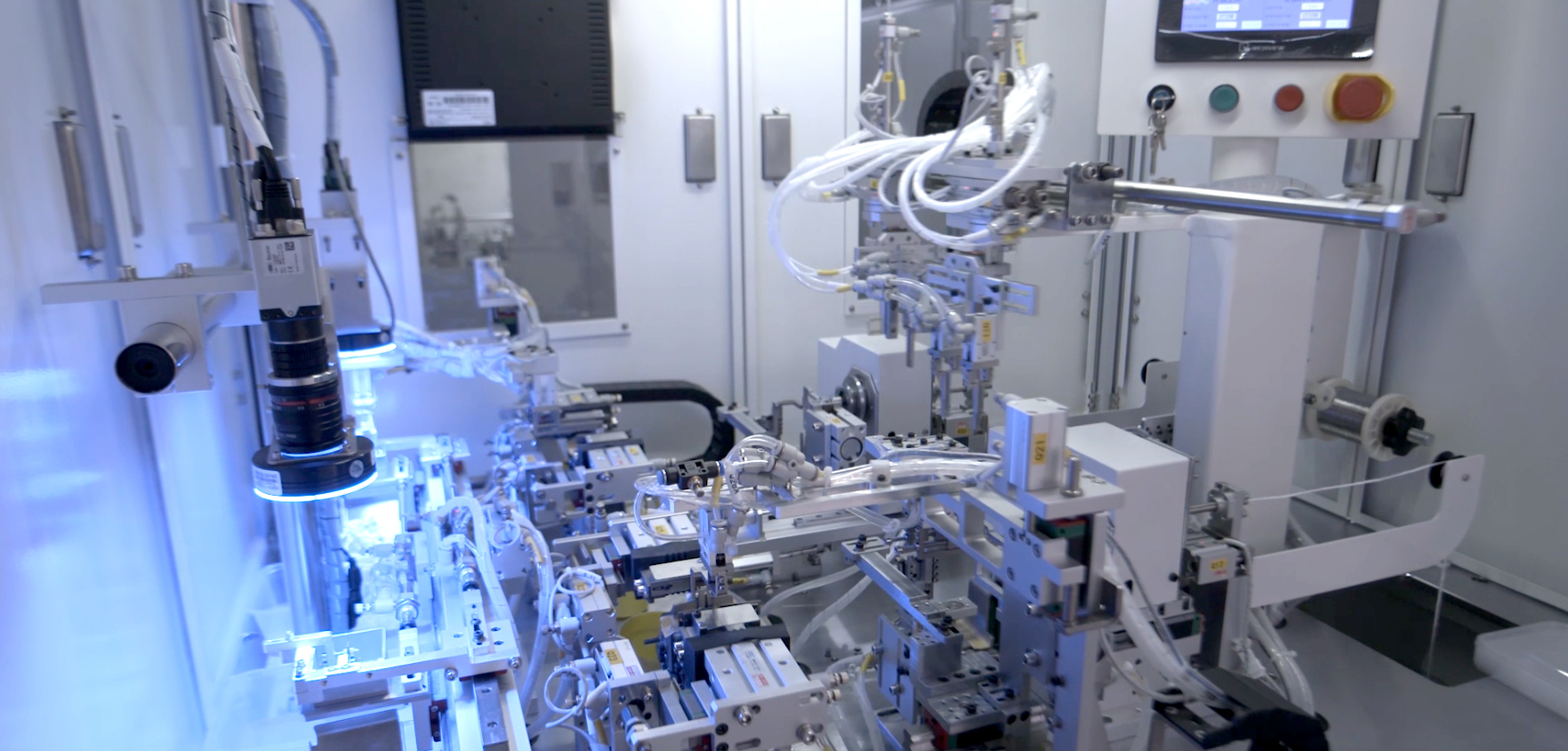

In addition to technological innovation, HCD also places great emphasis on product quality control. All of the company's atomizer coils are automatically produced in a GMP dust-free environment, undergo rigorous inspection through more than nine process steps, and pass international standards testing such as RoHS, REACH, and FDA to ensure product safety and stability. This unwavering commitment to quality has earned HCD's products a strong reputation and the trust of users.

HCD has also conducted in-depth research and exploration into the issue of oil leakage from transparent oil tanks in the electronic vaporizer market. The company has provided a series of effective solutions, focusing on multiple aspects, including oil cup structural design, oil-conducting medium selection, and airway optimization. The implementation of these solutions has not only significantly reduced the incidence of oil leakage but also improved user experience and satisfaction.

Customer needs: customized services lead the market

HCD deeply understands that customer needs are the driving force behind its development. Therefore, the company consistently prioritizes customer focus and provides customized services with innovative value. Whether it's standard products or samples, HCD can quickly deliver samples and complete the development and delivery of customized products within standard timeframes. This efficient and flexible service model enables Huachengda to better meet the individual needs of its customers, helping it stand out in a fiercely competitive market.

In addition,HCD operates five major production facilities, with an annual production capacity exceeding 2 billion atomizer cores. Through large-scale, centralized automated production and bulk, centralized material procurement, the company effectively reduces manufacturing and incoming material costs. This cost advantage enables Huachengda to offer customers more reasonable pricing while ensuring product quality.

Looking to the future: Continuous innovation leads industry development

Looking ahead, HCD will continue to leverage its exceptional technical expertise and industry leadership to drive the development of atomization technology. The company will continuously invest in R&D, deepen technological innovation and product development, and provide global customers with safer, more efficient, and environmentally friendly atomizer core products. At the same time, Huachengda will proactively respond to market changes and challenges, continuously meet the diverse needs of customers, and make greater contributions to the industry's continued innovation and healthy development.

来源:HCD华诚达

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.