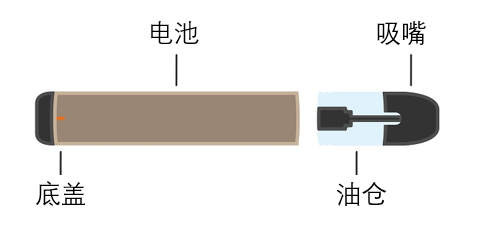

The oil tank is the structural component of the cartridge-type electronic cigarette that holds the oil. The main performance requirements are heat resistance, chemical resistance, high impact resistance, dimensional stability, food safety, etc.

The transformation wave of cartridge-type e-cigarettes continues, so oil tank materials are expected to continue to benefit from subsequent trends. In terms of material types, PCTG is the mainstream application in the industry. In addition, transparent nylon also has practical application cases.

1. PCTG

PCTG can be said to be the "leader" of e-cigarette oil tank materials.

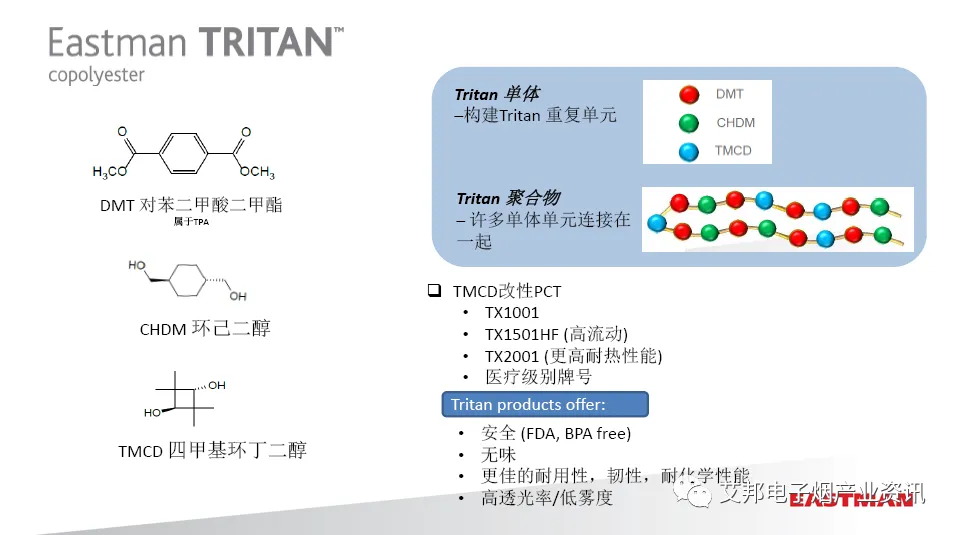

From 2018 to date, PCTG has been the mainstream application of oil tank materials, especially Eastman's TRITAN series, Tritan TX1501 HF, Tritan TX1001, etc. In addition to Eastman, other PCTG material manufacturers are also constantly exploring the e-cigarette application market, such as SK Chemicals, Dawn Chemical, etc.

PCTG was previously used in cosmetic packaging and plastic water cups because of its glass-like transparency and density close to that of glass, the fact that it does not contain bisphenol A, and its excellent food hygiene and flame retardancy. In electronic cigarettes, PCTG’s performance advantages lie in its chemical resistance, heat resistance, and transparency. It can be used to make oil tanks, bases, nozzles, top covers and other parts.

Compared with the processing of ordinary plastic raw materials, the processing of PCTG has the following three significant characteristics:

1. PCTG needs to use low mold temperature. The recommended mold temperature is 15-40℃, the lower the better;

2. PCTG plastic pellets must be fully dried ;

3. The processing temperature of PCTG should not be too high, injection molding at 240-260 ℃, extrusion and blow molding at 190-220 ℃.

Although it is a mainstream solution, PCTG also has shortcomings and has caused headaches for many injection molding factories. For example, it has high drying requirements and can be easily scrapped if not handled with care, and the defective rate has remained high. In addition, the head effect of material factories is obvious, which leads to higher prices and easily limited production capacity.

2. Transparent nylon

Transparent nylon is not inferior to PCTG in terms of heat resistance, chemical resistance, and transparency, especially chemical resistance, where it performs better and is beginning to emerge in CBD e-cigarettes.

In March 2025, Ispire teamed up with Raw Garden to launch the PA12 material integrated CBD e-cigarette Sprout™.

Transparent nylon is a polymer material with excellent comprehensive properties. It not only has the advantages of high mechanical strength, good thermal stability, excellent corrosion resistance, but also has the advantages of easy molding, dimensional stability, small linear expansion coefficient, high cost performance, excellent electrical insulation and aging resistance, non-toxicity, odorlessness, and easy to form alloys with other amorphous or semi-crystalline polyamides.

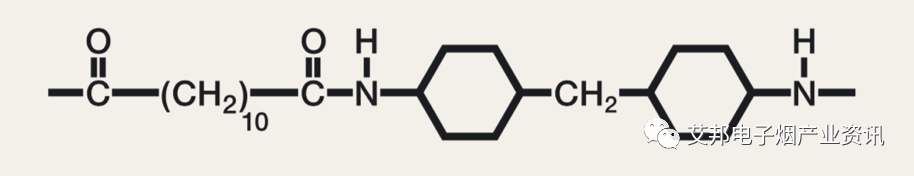

Figure PACM12 structure

On the one hand, it has excellent transparency (even higher than PC and close to PMMA), and on the other hand, it is superior to general transparent polymer materials (such as PS, PC, PMMA, etc.) in terms of resistance to environmental stress cracking, oil solvent resistance, scratch resistance, and wear resistance. Common types of transparent nylon include PA MACM12, PA 12/MACMI, PA 6I/X and so on.

Currently, transparent nylon can be used to make mouthpieces, oil tanks and other structural parts in electronic cigarettes. Companies that make transparent nylon raw materials include Evonik, EMS, Arkema, Shandong Guangyin, Shandong Xianglong and other companies.

Similarly, transparent nylon also has a disadvantage, which is that it is more expensive than PCTG. Therefore, the most common material used in CBD electronic cigarettes is high-strength glass.

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.