Common materials used for e-cigarette casings include ABS plastic, PC polycarbonate (PCTG).

- ABS plastic is chemically and heat-resistant, highly elastic and tough, has good processability, and is relatively low-cost, making it suitable for e-cigarette casings.

- PC plastic offers high transparency, strong impact resistance, and heat resistance, making it suitable for products with transparent or translucent casings.

- PCTG is widely used in various e-cigarette components due to its safety, transparency, toughness, and high-temperature resistance.

The manufacturing process for e-cigarette plastic casings includes design and development, mold making, injection molding, post-processing, assembly, and packaging. These steps ensure that the product's appearance and performance meet high standards.

I. Common Materials for E-cigarette Plastic Shells

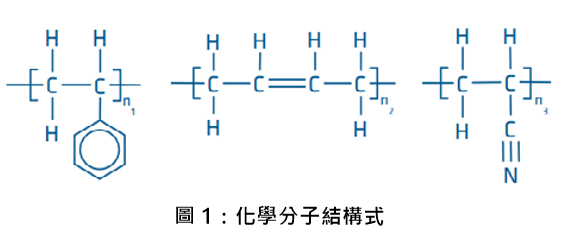

1. ABS

ABS plastic is a terpolymer of acrylonitrile (A), butadiene (B), and styrene (S). The relative proportions of the three monomers can be varied to create a variety of resins.

ABS plastic combines the properties of all three components. A provides chemical and heat resistance, along with a certain surface hardness; B imparts high elasticity and toughness; and S imparts thermoplastic processing and molding properties, improving electrical properties.

ABS plastic is widely used in electronic cigarette housings due to its good mechanical properties, processing performance and relatively low cost. It has good impact resistance, firmness and high thermal stability.

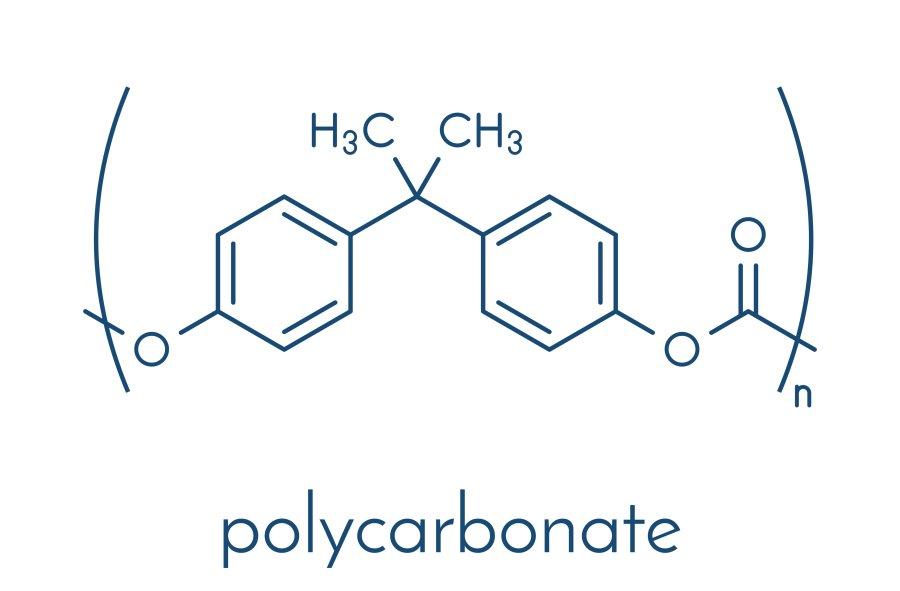

2. PC

Polycarbonate is a tough thermoplastic resin, named after the -O-C(=O)-O- group within it. It can be synthesized from bisphenol A and phosgene (COCl2). The most commonly used method is the melt transesterification process (synthesized by bisphenol A and diphenyl carbonate through transesterification and polycondensation).

PC plastic offers exceptional transparency and impact resistance, as well as excellent heat resistance, making it suitable for e-cigarette products requiring transparent or translucent casings.

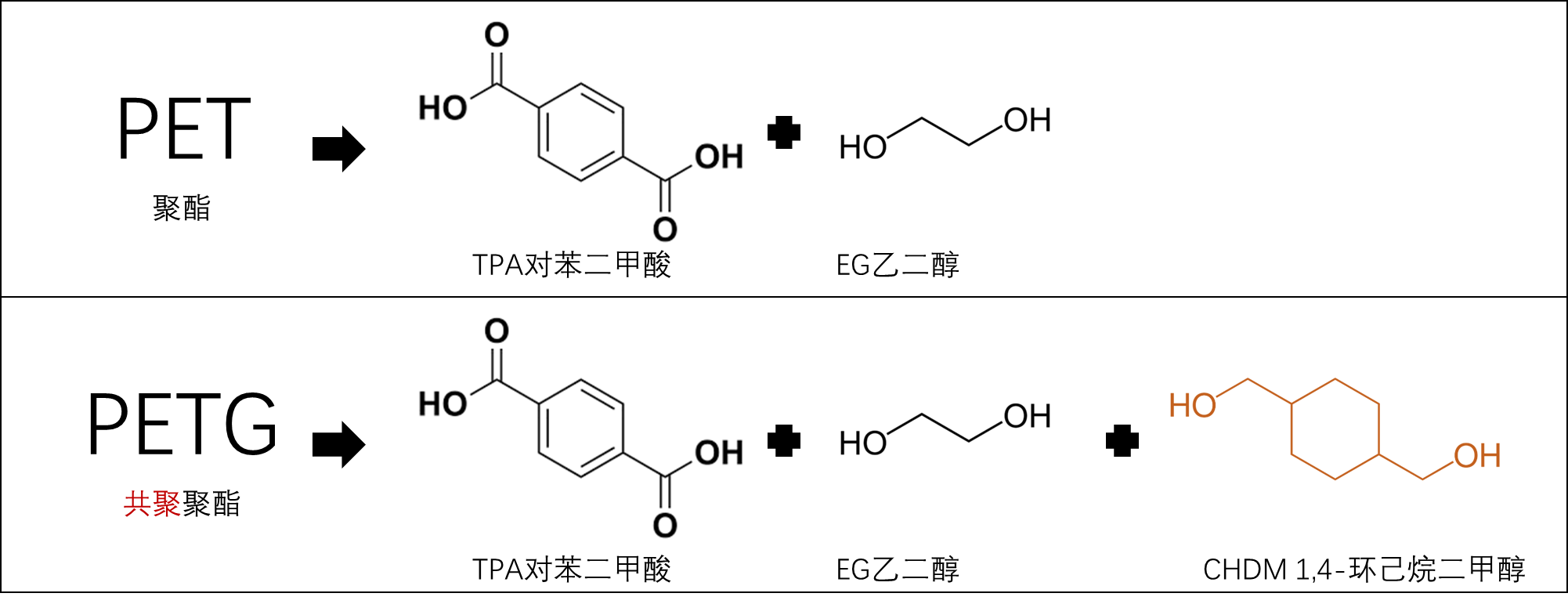

3. PCTG

PETG, or cyclohexanedimethanol-modified copolyester, is a copolymer produced by replacing some of the ethylene glycol in the PET synthesis process with other diols (comonomers).

It is further categorized based on the proportion of the comonomer CHDM. According to some sources, copolyesters with a CHDM content greater than 50% are called PCTG, while those with a CHDM content less than 50% are called PETG.

PCTG material is widely used in oil storage tanks, atomization tanks, bases, nozzles, top covers and other components due to its excellent properties such as safety, high transparency, good toughness and high temperature resistance.

II. The Development Process for E-Cigarette Plastic Cases

The process primarily includes the following steps:

1. Design and Development:

- 3D Modeling: Design a 3D model of the e-cigarette case using software such as C4D.

- Prototyping: Prototypes are produced using 3D printing or CNC machining for testing and verification.

2. Mold Production:

- Mold Design: Detailed mold design is performed based on the final product design.

- Mold Processing: Molds are produced using high-precision CNC machining centers, electrical discharge machining (EDM), grinders, and other equipment.

3. Injection Molding:

- Material Selection: Select the appropriate plastic material based on product requirements.

- Injection Molding: Plastic pellets are heated to a molten state and then injected into the mold cavity. Cooling and solidification occurs under high pressure to form the mold.

- Demolding: The molded plastic case is removed from the mold after cooling to a certain degree.

4. Post-Processing:

- Deburring: Removes burrs and flash generated during the molding process.

- Grinding and Polishing: The surface of the housing is ground and polished to achieve the desired finish.

- Painting and Coloring: If a specific color or texture is desired, the housing can be painted or colored.

- Printing: Patterns, logos, or text can be added to the housing through screen printing, pad printing, or digital printing.

5. Assembly:

- Assembly: The plastic housing is assembled with other e-cigarette components (such as the battery, atomizer, and circuit board).

- Quality Inspection: The assembled e-cigarette is inspected for functionality and quality.

6. Packaging:

- Final Inspection: A final quality and functional inspection is performed before packaging.

- Packaging: The product is packaged according to product requirements for easy storage and shipping.

These steps may vary depending on the specific product design and the manufacturer's process. For example, some housings may require additional processing such as laser engraving, heat transfer printing, water transfer printing, or special surface coatings. High-quality e-cigarettes often require precise molds and intricate processing to ensure that the product's appearance and performance meet high standards.

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.