Printing process

1.The printed surface of the product must be flat and consistent (three layers of printing are recommended).

2.The screen requirements are as shown below (for reference only).

4. Printing Parameters: Screen pitch 1.4mm, printing pressure 1kg, printing speed 60, ink return speed 80.

5. Drying: After printing, dry at 150°C for half an hour.

6. Sintering: Requires a vacuum sintering furnace with a vacuum level below 10 Pa.

Sintering process

Heat to 350℃ in 30 minutes and keep warm for 30 minutes → continue heating to 600℃ for 30 minutes and keep warm for 30 minutes → continue heating to 870℃ for 60 minutes, then keep warm for another 30 minutes and cool naturally to room temperature → vacuum degree is below 10 Pa.

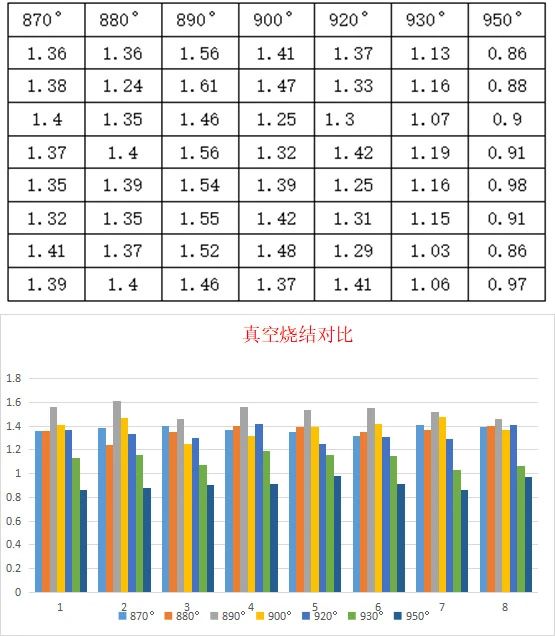

Comparison of sintering temperature curves

来源:建宇网印

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.