一次性电子烟,顾名思义,是一次性消耗的电子烟产品,是目前电子烟出口品类中占比最高的一种。中国电子商会电子烟行业委员会的报告显示,2021年中国电子烟出口预估1383亿人民币,其中一次性小烟占比65%。

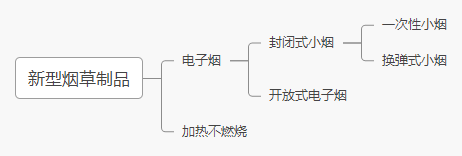

常见的新型烟草制品

一次性电子烟的构造主要有雾化组件、电池、外壳,其中常见的外壳材质是两种,分别是铝合金和塑胶(PC、ABS、PCTG中的一种或复合),消费市场的需求变化使得一次性小烟塑胶外壳的占比快速上升,因为先进的注塑工艺可以带来低成本、多样化的外观设计。

如今,一次性小烟塑胶外壳的发展趋势有望从热门的双色注塑工艺,逐步转到生物降解环保材料的替代上。

-

2022年1月,电子烟油生产商 Riot Labs 宣布推出了一款低碳一次性电子烟——QBAR,外壳由来源于玉米淀粉的PLA塑料制成;

-

2022年5月,电子烟公司卓力能计划2023 年年中在全球推出可生物降解的电子烟产品,塑料部件采用了PBS等创新的可生物降解原材料。

-

行业内初步了解,其他的一次性电子烟厂商也有相关的布局。

Image: Riot Labs,tobaccoreporter

Biodegradable plastic refers to a type of plastic whose various properties meet the requirements of use during the storage period and can be degraded into environmentally harmless substances under natural conditions after use. It is considered to be one of the effective ways to solve the problem of plastic pollution.

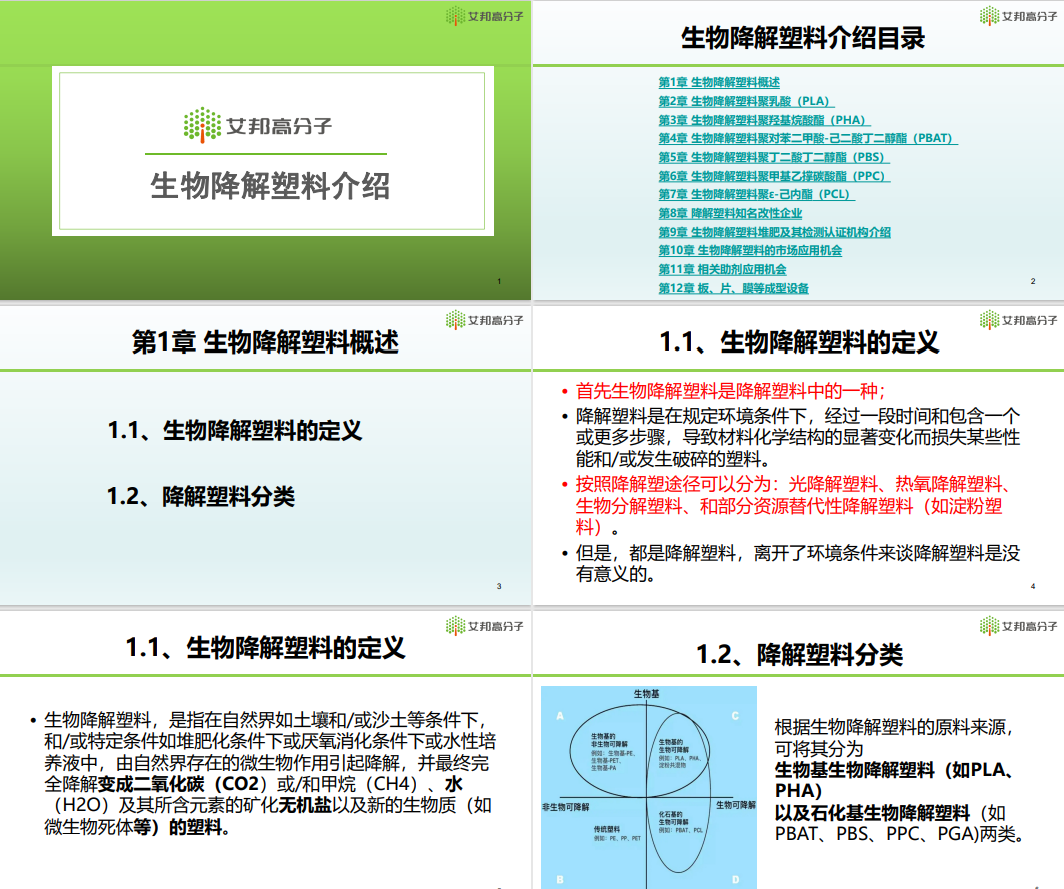

那么,本篇就一起来简单唠一唠,都有哪些生物可降解塑料呢?目前常见的有PLA、PBAT、PHA、PCL、PBS、PPC等等。

常见的可生物降解塑料及其命名缩写

|

序号 |

命名缩写 |

可生物降解塑料 |

|

1 |

PLA |

聚乳酸 |

|

2 |

PBS |

聚丁二酸丁二醇酯 |

|

3 |

PBSA |

聚(丁二酸-co-己二酸丁二醇酯) |

|

4 |

PBAT |

聚(对苯二甲酸-co-己二酸丁二醇酯) |

|

5 |

PHA |

聚羟基脂肪酸酯 |

|

6 |

PPC |

聚碳酸亚丙酯 |

|

7 |

PCL |

聚己内酯 |

1、PLA

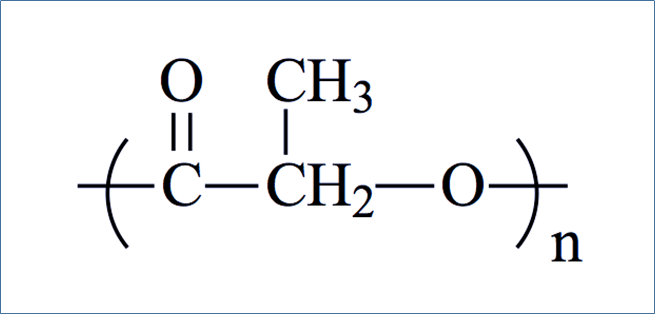

PLA是聚乳酸的英文简称,英文全称是Polylactic Acid 或 Polylactide,是 α-羟基丙酸缩合的产物,属于热塑性脂肪族聚酯的一种。

PLA结构式

PLA is a light yellow transparent solid with good thermal stability. Its processing temperature is 170-230℃. It has good solvent resistance and can be processed in a variety of ways, such as extrusion, spinning, biaxial stretching, and injection blow molding.

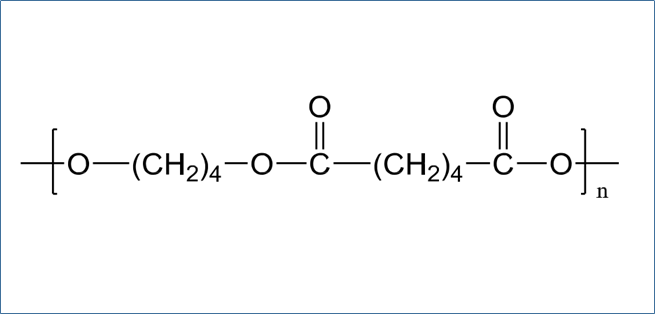

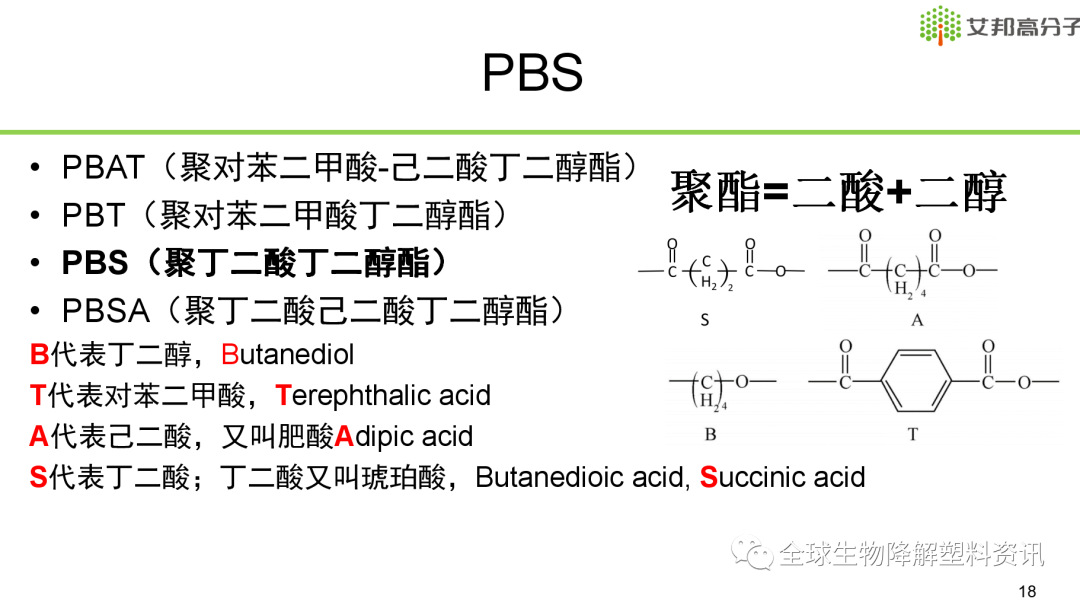

2、PBS

PBS, which is called polybutylene succinate in Chinese, is a type of polyester. It is made of aliphatic succinic acid and butanediol as the main raw materials. Due to the limited raw materials of succinic acid in my country, PBS derivatives PBAT and PBSA were born. The following is the structural formula of PBS, the structural formula of each monomer, and the names of various polyesters.

PBS结构式

PBS has the advantages of good heat resistance, good softness, good compatibility, and low-temperature heat sealing, but PBS has poor transparency and low tear strength.

In addition to the above characteristics, PBS has very good processing performance and can be used for various molding processes on general processing equipment. It has the best processing performance among the general-purpose biodegradable plastics. Almost all molding and processing methods used for current resin materials (blow molding, injection molding, extrusion molding, sheet molding, foam molding, vacuum molding, etc.) can be applied to the processing of PBS.

3、PBAT

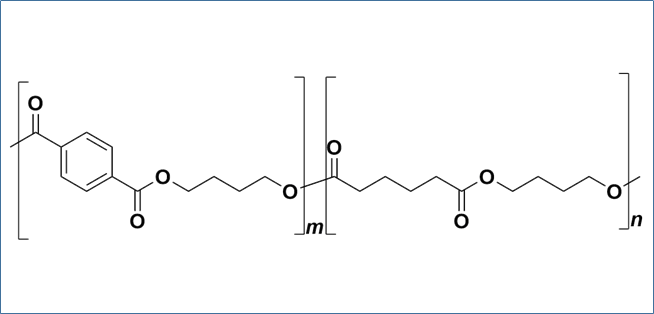

PBAT, whose Chinese name is polybutylene terephthalate-adipate, has the structural formula shown in the figure below.

PBAT结构式

PBAT is a semi-crystalline polymer with a crystallization temperature of around 110°C, a melting point of around 130°C, and a density between 1.18g/ml and 1.3g/ml. The crystallinity of PBAT is about 30%, and the Shore hardness is above 85. It has good ductility, elongation at break, heat resistance, and impact resistance.

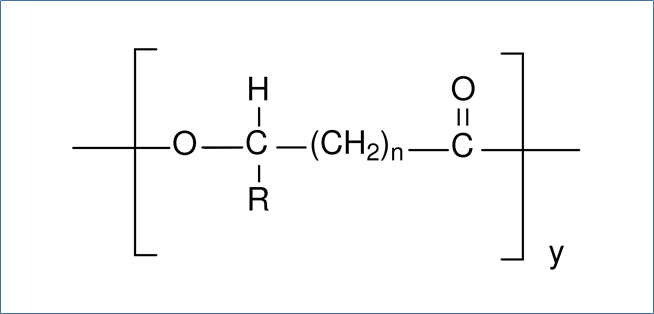

4、PHA

聚羟基烷酸酯( polyhydroxyalkanoates 简称PHA) ,PHA是由微生物通过各种碳源发酵而合成的不同结构的脂肪族共聚聚酯,其中最常见的有聚3-羟基丁酸酯(PHB)、聚羟基戊酸酯(PHV)及PHB和PHV的共聚物(PHBV),其基本结构如下图。

PHA结构式

As a natural polymer material, PHA has the basic characteristics of common polymers, such as thermoplasticity or thermal processability. At the same time, PHA also has some special material characteristics, such as nonlinear optical activity, piezoelectricity, gas barrier properties, etc. Its basic properties are similar to those of polypropylene.

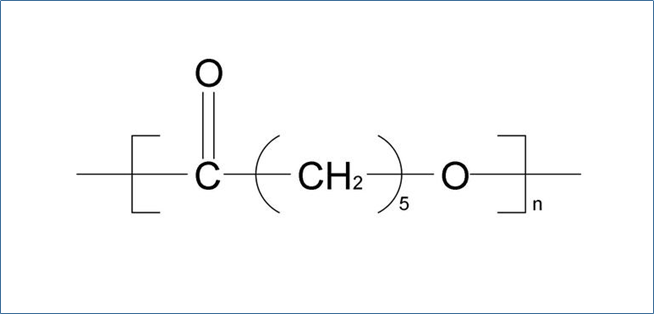

5、PCL

Poly-ε-caprolactone (PCL) is a low-melting-point polymer obtained by ring-opening polymerization of ε-caprolactone, and its melting point is only 62°C.

PCL结构式

Compared with PLA, PCL has better hydrophobicity, but its degradation rate is slower; at the same time, its synthesis process is simple and the cost is low. PCL has excellent processing performance and can be made into films and other products using ordinary plastic processing equipment.

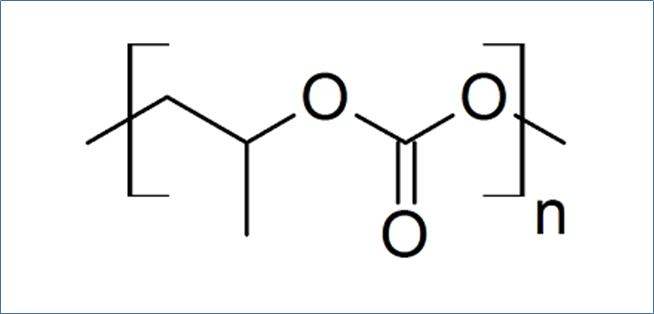

6、PPC

Polypropylene carbonate, abbreviated as PPC (Polypropylene carbonate), is an aliphatic polyester synthesized from carbon dioxide (CO2) and propylene oxide.

PPC结构式

As a new type of thermoplastic polymer, PPC has a series of excellent characteristics such as good biocompatibility, high barrier properties, impact resistance, transparency and non-toxicity.

关注公众号,发送关键词“生物降解”

即可获取更全面的生物降解材料报告!

以上是常见的几种生物降解塑料介绍,而从目前已知的一些信息来看,在电子烟上已经有实际应用案例的是PLA,就是那款QBAR,而卓力能所布局的并不能确定是PBS,有可能也是PLA,有可能是PBAT,或者其他。

值得注意的是,生物降解材料提供商在这方面已经有了相应的解决方案,光华伟业、金发科技均有相应解决方案。

《关于促进电子烟产业法治化规范化的若干政策措施(试行)》中第三十八条提出,要推进电子烟产业绿色化,降低产品能耗、水耗和污染物排放,落实绿色企业和产品的评价体系和认证标准,推动先进绿色技术研发与应用。完善废弃烟弹、烟具回收和再利用体系,规范烟弹、烟具回收处理流程。推动清洁绿色能源利用与传统能源循环利用。

因此,在这些因素的推动下,生物降解塑料有望在一次性电子烟外壳应用上大放光彩。

END

原文始发于微信公众号(艾邦新消费电子资讯):一次性电子烟掀起环保浪潮,生物降解塑料备受关注

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.