气凝胶陶瓷功能材料——雾化芯的迭代技术

摘要:

随着电子雾化产业的发展,雾化芯作为核心部件逐渐成为技术创新和行业变革的关键。紫荆未来科技提出了SiC气凝胶陶瓷雾化芯技术,通过气凝胶陶瓷制备和芯材烧结技术,实现了气凝胶陶瓷雾化芯的革命性突破。该技术克服了传统雾化芯孔隙不一致和掉粉问题,提升了雾化效率和口感体验。依托强大的科研团队和产学研合作,紫荆未来科技在新型雾化芯技术上取得了领先地位,并积极拓展在多元领域的应用,助力产业加速迭代。

大空间消杀、医疗美容、消费类电子雾化器……随着使用场景越来越丰富,电子雾化产业正逐渐成为一个新千亿级市场。

作为电子雾化器最核心的部件,雾化芯一直以来是中国电子雾化行业的"兵家必争之地",推动着一轮又一轮的科技创新和行业变革。

迭代,一直在雾化芯技术上发生。从最早的玻纤芯到电阻丝棉芯直至陶瓷雾化芯,雾化芯经历了数次更迭,对发热均匀度、陶瓷强度及陶瓷雾化能效的要求不断提高。然而,目前市面上主流的陶瓷雾化芯普遍面临一系列问题:

首先,足够的导油能力需要较大的气孔率和较小的陶瓷纤维孔径,但会影响陶瓷雾化芯的强度;另一方面,为了保证口感,又需要足够小的陶瓷纤维孔径,现有陶瓷材料难以达到这种平衡。此外,陶瓷烧结和表面的金属化方法在实现过程中也面临诸多技术挑战……

面对这些痛点,新入局的企业正不断锐意求新、探寻突破。

记者留意到,位于"雾谷"深圳的紫荆未来科技有限公司(以下简称"紫荆未来科技")提出最新技术概念——SiC气凝胶陶瓷雾化芯(以下简称"气凝胶陶瓷雾化芯"),正凭借强大的科研实力成为雾化领域下一个值得关注的企业。

气凝胶陶瓷制备+芯材烧结

造就国际首款气凝胶陶瓷雾化芯

目前,紫荆未来科技正聚焦于深入研究新材料前沿技术及雾化技术,将新材料新技术应用到各个雾化场景。其中,气凝胶陶瓷功能材料则是该公司近几年研发的重要成果。

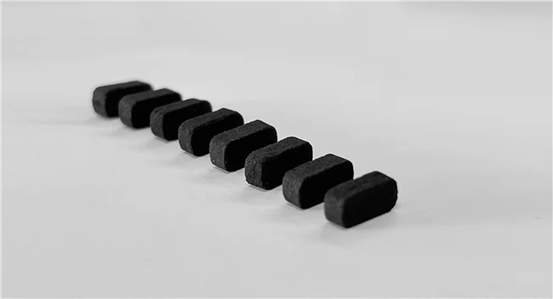

国际首款SiC气凝胶陶瓷雾化芯

"我们研发的国际首款气凝胶陶瓷雾化芯,将为雾化芯产品带来全新技术概念。这款雾化芯可采用整面镀层电极技术取消印刷电极,发热均匀稳定、发雾雾滴D90直径<1.65μm。"紫荆未来科技创始人吴海明表示。

气凝胶陶瓷雾化芯,何以成为下一个雾化芯高地,引领行业迈向新的发展阶段?带着这样的疑问,记者来到位于深圳龙岗区紫荆未来科技办公室,向吴海明详细地了解气凝胶陶瓷雾化芯背后的五大核心技术:

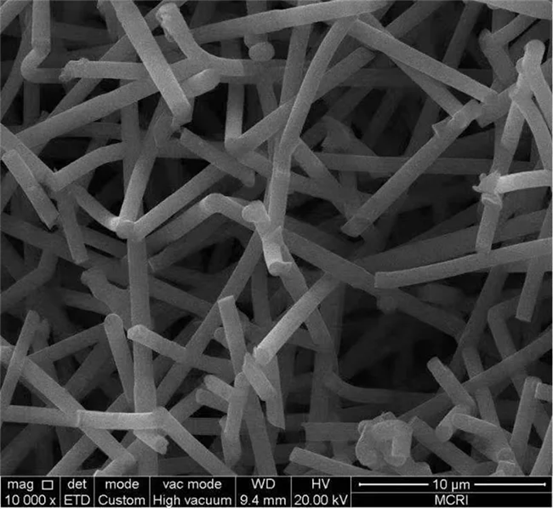

"现阶段,气凝胶陶瓷芯取得的革命性突破,很大程度上依赖于气凝胶陶瓷制备技术。"他介绍道,"传统的雾化技术需要采用蜡进行造孔,传统陶瓷芯烧结后的气孔都像蚯蚓状弯曲,这就导致了孔隙不一致和掉粉问题,口味还原不好、漏油和粉末易析出。而紫荆未来科技掌握的气凝胶功能陶瓷技术,其烧结后的孔隙都是直列式,孔隙率可高达85%。就像是三车道变成了八车道一样,烟油的流通性大幅提高。同时,还可以通过关闭部分气孔来减少烟油流通,也就意味着我们可以根据需要灵活调整。"

其次,是芯材烧结增强技术。目前市面上的陶瓷芯到65%的气孔结构已是极致,气孔率再高就脆了、不成形了,容易烧坏、烧塌。气流就像是雾化器的油门,气流越大意味着瞬间升温就越快,气流越小意味着升温就慢。针对不同的行业、不同的烟油,紫荆未来科技的气凝胶陶瓷雾化芯适配了不同的沸点、雾化点。"在气雾比上,举个例子,气推进去,然后高温雾化出来的烟雾可以控制气流跟雾量,口感、体验感就更好了,不会浓得呛人,也不会淡得没有味道。"吴海明说。

国际首款SiC气凝胶陶瓷雾化芯

目前市场上最常见的丝网状发热丝,在使用过程中容易结痂堵塞,紫荆未来科技采用液体金属印刷技术,通过改变发热丝的形态,将液体金属浇灌在陶瓷雾化芯上,使其呈块状,液体金属就可以在高温环境下牢牢嵌入纤维之中,陶瓷精准控温的难题得以解决。

吴海明解释道:"若陶瓷孔隙不够,被金属浇灌的陶瓷就如同被灌水的蚂蚁窝,结构被拉垮成颗粒状。我们需要金属既深入陶瓷的纤维孔隙中,又附着在上面不掉块。由于金属和陶瓷密度不同,在一体化烧结过程中对高温的承受能力也不一样,这是一项很难掌握的技术。"

紫荆未来科技的封装切割技术,恰恰是及时响应客户需求的妙招。吴海明说:"有了强大的设计能力,就可以依客户具体需求快速定制凹槽的薄厚度,并通过封装切割灵活调配。比如,雾化芯油槽是可以个性化配套的,能够根据客户需求调整烟雾量的大小。"

值得一提的是,紫荆未来科技在雾化芯上采用的仿真结构设计,通过测试计算不同状态、年龄人群的呼吸肺活量,模拟数字仿真结果,据此优化雾化芯的结构参数,应用在传感器部分,对大小气孔数量及各种数据精确调控,以达到提高雾化效率、减少有害物质生成、改善口感等目的。

气凝胶陶瓷雾化芯微孔形貌

通过成熟且完美的工艺,紫荆未来科技的气凝胶陶瓷雾化芯达到国际领先水平,取得了雾化器行业颠覆性的成果:气凝胶脆性降低、"掉粉"问题得以解决;最高使用温度达1500℃,远高于常规气凝胶的使用温度上限650℃;具有显著更高的力学强度,同时仍能保持优异的可压缩性/回弹性;在高强度的情况下气孔率比现有市面产品提升30%,口感与现有产品相比更加细腻……一步到位解决"气、雾、油、温、电"五大雾化芯关键环节痛点,气凝胶陶瓷雾化芯进一步强化了紫荆未来科技在雾化芯技术上的优势地位。

"一重两院两所"

构建强大产学研实力

气凝胶陶瓷雾化器的成功研发,离不开顶尖高校和头部研究所的支持贡献。产学研合作使得紫荆未来科技具备强大的科研实力,为雾化器技术的进步提供了强有力保障。

据了解,紫荆未来科技的核心技术团队来自西安交通大学材料强度国家重点实验室。该实验室先后主持国家自然科学基金、国家"863"项目、军品配套项目、教育部"新世纪优秀人才培养计划"项目、陕西省科技攻关计划等多项,先后参加多孔透波材料、陶瓷金属焊接军工预研项目、国家自然科学基金重点项目、"九五"国家重点攻关等项目。

经过近5年的持续研发,实验室成功开发出全新的用以合成具有优异可压缩性/弹性的硅基陶瓷纤维气凝胶,申请并获得多项发明专利,拥有完全的自主知识产权。

西安交通大学材料强度国家重点实验室

此外,紫荆未来科技雄厚的院校背景可以用"一重两院两所"来概括。其中"一重",指的是清华大学国家功能陶瓷重点实验室——依托清华大学的强大科研能力,该实验室目前拥有全中国顶级的多孔陶瓷设备检测仪器。

"两院",分别指清华大学材料学院、西安交通大学材料学院(气凝胶纤维生长技术与气凝胶陶瓷纤维增强技术在此研发);"两所"则包括中科院力学研究所、中科院工程热物理研究所。

据吴海明透露,目前,紫荆未来科技正加速打造"一中心一基地一工厂"三大基地布局。其中,"一中心"将落户深圳清华大学研究院智能雾化传感技术工程中心,将聚焦研发、工艺、测评、专利技术、人才引进等方面;深圳宝安区福永中试基地则聚焦消费类电子雾化器件,负责测试配对、联合研发、工艺路线各项专利申请;东莞数智化工厂则负责智能化、自动化、数据化、可视化、灯塔工厂等。

紫荆未来科技的顾问团队同样实力强大,成员分别来自清华大学、中国科学院、赛迪研究院、CHITECH……专家学者们的经验和专业知识为紫荆未来科技的科研工作提供了宝贵的指导和支持。

依托不断夯实的科研力量及越发成熟的技术矩阵,紫荆未来科技正不断推进

气凝胶陶瓷雾化器的技术进步,为行业的发展及更多领域贡献更多的科研成果和技术创新。

积极拓展多元布局

助力产业加速迭代

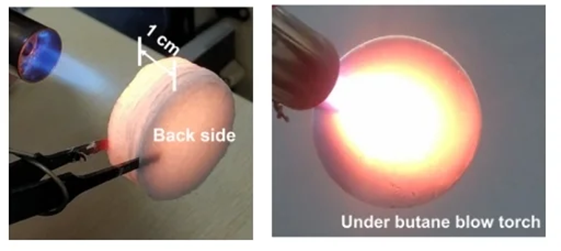

当下,随着全球各大电子雾化市场的政策法规逐步完善,"雾谷"深圳的产业链和技术能力正逐渐走向成熟。坚持以"技术+产品"为核心竞争力的紫荆未来科技正在积极拓展多元化布局,目前已研发出气凝胶毡/块/板、超级隔热SiC气凝胶、Si3N4气凝胶毡产品,同时积极探索气凝胶石墨雾化芯在未来的更多可能性。

Si3N4 气凝胶毡与超级隔热SiC气凝胶

未来,紫荆未来科技还将赋能更多产业发展,持续助力产业迭代。吴海明表示,将向三个方向拓展雾化器产业布局:"一是消费类电子雾化器,这一市场已告别野蛮生长时代,朝着更成熟更规范化方向发展,必将加速行业马太效应;二是医疗雾化行业,过去医院用超声水溶性的雾化技术,患者在医院做雾化只能十几分钟坐着不动,以后可以通过恒定口腔温度雾化、便携式雾化药剂等技术,给患者更加轻松舒适的治疗体验;三是农用及家用雾化及密闭空间消杀供氧领域,以此为人们提供更方便、舒适的生活环境。"

吴海明对雾化芯技术的明天充满了期待,他相信,有朝一日,该技术甚至还可以在航空航天、极端条件、军事设备等更为广泛的领域得到应用。

"紫荆未来科技的愿景是——引领科技,成为雾化领域的上市公司。"这一目标的实现已然被提上了日程,吴海明对前景充满信心。他表示,对于雾化行业而言,陶瓷芯的创新与应用还有很多可能性,紫荆未来科技将在引领雾化科技创新潮流、助力产业迭代之路上持续精进。

Aerogel Ceramic Functional Materials - The Iterative Technology of Vaping Cores

With increasingly diverse usage scenarios such as large-space disinfection, medical beauty, and consumer electronic atomizers, the electronic vaping industry is gradually becoming a new market worth hundreds of billions.

As the most critical component of electronic atomizers, the vaping core has always been a highly contested area in China's electronic vaping industry, driving rounds of technological innovation and industry transformation.

Iteration is continually happening in vaping core technology. From the earliest glass fiber cores to resistance wire cotton cores and now to ceramic vaping cores, vaping cores have undergone several iterations, with increasing demands for heating uniformity, ceramic strength, and ceramic vaping energy efficiency. However, mainstream ceramic vaping cores in the market generally face a series of problems:

Firstly, sufficient oil-conducting capability requires a high porosity and smaller ceramic fiber pore size, but this affects the strength of the ceramic vaping core. On the other hand, to ensure a good taste, a sufficiently small ceramic fiber pore size is needed, which existing ceramic materials struggle to balance. In addition, the ceramic sintering and metallization methods on the surface also face many technical challenges in the implementation process...

Faced with these pain points, new entrants to the industry are constantly seeking innovation and breakthroughs.

The reporter noticed that Bauhinia Future Technology Co., Ltd. (hereinafter referred to as "Bauhinia Future Technology"), located in the "Fog Valley" of Shenzhen, proposed the latest technological concept - SiC aerogel ceramic vaping core (hereinafter referred to as "aerogel ceramic vaping core"), which is becoming the next noteworthy enterprise in the vaping field with its strong scientific research strength.

Aerogel Ceramic Preparation + Core Material Sintering

Creating the World's First Aerogel Ceramic Vaping Core

Currently, Bauhinia Future Technology is focusing on in-depth research into cutting-edge new material technology and vaping technology, applying new materials and technologies to various vaping scenarios. Among them, aerogel ceramic functional materials are an important result of the company's research and development in recent years.

The World's First SiC Aerogel Ceramic Vaping Core

"Our developed world's first aerogel ceramic vaping core will bring a new technological concept to vaping core products. This vaping core can use the whole face plating electrode technology to eliminate printed electrodes, achieving uniform and stable heating, and the atomized droplet D90 diameter is less than 1.65μm," said Wu Haiming, the founder of Bauhinia Future Technology.

What makes the aerogel ceramic vaping core the next high ground for vaping cores, leading the industry to a new stage of development? With such questions, the reporter came to the Bauhinia Future Technology office in Longgang District, Shenzhen, to learn in detail about the five core technologies behind the aerogel ceramic vaping core from Wu Haiming:

"At the current stage, the revolutionary breakthrough achieved by the aerogel ceramic core relies heavily on aerogel ceramic preparation technology," he explained. "Traditional vaping technology requires the use of wax for pore formation, and the pores in traditional ceramic cores after sintering are all worm-like and curved, leading to inconsistency in porosity and powder shedding issues, poor taste restoration, and oil leakage and powder exudation. However, the aerogel functional ceramic technology mastered by Bauhinia Future Technology results in straight-lined pores after sintering, with a porosity rate that can reach up to 85%. It's like changing from three lanes to eight lanes, significantly improving the fluidity of the e-liquid. At the same time, it is also possible to reduce the e-liquid flow by closing some pores, which means we can flexibly adjust according to needs."

Secondly, there is the core material sintering enhancement technology. Currently, the market's ceramic cores with a 65% porosity structure are already at their limit; any higher porosity and they become fragile, misshapen, easily burned, or collapsed. Airflow is like the throttle of an atomizer; the greater the airflow, the faster the instantaneous temperature rise, and the smaller the airflow, the slower the heating. For different industries and e-liquids, Bauhinia Future Technology's aerogel ceramic vaping cores are adapted to different boiling points and vaping points. "For example, in terms of the air-to-liquid ratio, air is pushed in, and then the high-temperature atomized smoke can control the airflow and the amount of mist. The taste and experience are better, not too strong to choke, nor too weak to taste," said Wu Haiming.

The most common heating wires on the market are prone to scabbing and clogging during use. Bauhinia Future Technology adopts liquid metal printing technology, changing the shape of the heating wire by pouring liquid metal on the ceramic vaping core, making it block-shaped. The liquid metal can then be firmly embedded in the fibers under high-temperature conditions, solving the difficult problem of precise temperature control of ceramics.

Wu Haiming explained: "If the ceramic porosity is not enough, the metal-poured ceramics are like ant nests filled with water, with the structure collapsing into particles. We need the metal to penetrate deep into the pores of the ceramic fibers and adhere to the surface without falling off. Due to the different densities of metal and ceramics, their ability to withstand high temperatures during the integrated sintering process is also different, which is a difficult technology to master."

Bauhinia Future Technology's packaging and cutting technology is precisely the clever solution to respond to customer needs in a timely manner. Wu Haiming said: "With strong design capabilities, we can quickly customize the thickness of the grooves according to specific customer needs and flexibly allocate through packaging and cutting. For example, the oil trough of the vaping core can be personalized to match, and the smoke volume can be adjusted according to customer requirements."

It is worth mentioning that Bauhinia Future Technology's simulation structure design used in the vaping core, through testing and calculating the respiratory lung capacity of different states and age groups, simulates digital simulation results, and optimizes the structural parameters of the vaping core based on this, applying it to the sensor part. It precisely controls the number of large and small pores and various data to achieve the goals of improving vaping efficiency, reducing the generation of harmful substances, and improving taste.

Through mature and perfect technology, Bauhinia Future Technology's aerogel ceramic vaping core has reached an international leading level, achieving disruptive results in the atomizer industry: the brittleness of aerogel is reduced, and the "powder shedding" problem is solved; the highest operating temperature reaches 1500°C, far exceeding the conventional aerogel's upper limit of 650°C; it has significantly higher mechanical strength while still maintaining excellent compressibility/rebound; under high strength, the porosity is increased by 30% compared to existing market products, and the taste is more delicate compared to existing products... Solving the five key pain points of "air, mist, oil, temperature, and electricity" in one go, the aerogel ceramic vaping core further strengthens Bauhinia Future Technology's advantageous position in vaping core technology.

"One Heavy, Two Academies, Two Institutes"

Building Strong Industry-University-Research Strength

The successful development of the aerogel ceramic atomizer cannot be separated from the support and contribution of top universities and leading research institutes. Industry-university-research cooperation has endowed Bauhinia Future Technology with strong scientific research strength, providing a strong guarantee for the advancement of atomizer technology.

It is understood that Bauhinia Future Technology's core technical team comes from the State Key Laboratory of Material Strength at Xi'an Jiaotong University. The laboratory has presided over various projects, including the National Natural Science Foundation, the National "863" Project, military product supporting projects, the Ministry of Education's "New Century Excellent Talent Training Program" project, Shaanxi Province's science and technology tackling plan, and has participated in projects such as porous wave-transmitting materials, ceramic-metal welding military pre-research projects, key projects of the National Natural Science Foundation, and "Ninth Five-Year" national key projects.

After nearly five years of continuous research and development, the laboratory has successfully developed a new type of silicon-based ceramic fiber aerogel with excellent compressibility/elasticity, applied for and obtained multiple invention patents, and has complete independent intellectual property rights.

In addition, Bauhinia Future Technology's strong academic background can be summarized as "One Heavy, Two Academies, Two Institutes." "One Heavy" refers to the National Functional Ceramic Key Laboratory of Tsinghua University - relying on Tsinghua University's strong scientific research capabilities, the laboratory currently has China's top porous ceramic equipment testing instruments.

"Two Academies" refer to the Materials College of Tsinghua University and the Materials College of Xi'an Jiaotong University (where aerogel fiber growth technology and aerogel ceramic fiber reinforcement technology are developed); "Two Institutes" include the Institute of Mechanics of the Chinese Academy of Sciences and the Institute of Engineering Thermophysics of the Chinese Academy of Sciences.

According to Wu Haiming, Bauhinia Future Technology is currently accelerating the construction of a three-base layout of "one center, one base, one factory." Among them, "one center" will be located at the Intelligent Vaping Sensing Technology Engineering Center of Tsinghua University Research Institute in Shenzhen, focusing on research and development, process, evaluation, patent technology, talent introduction, and other aspects; the Fuyong pilot base in Bao'an District, Shenzhen, focuses on consumer electronic vaping devices, responsible for testing pairing, joint research and development, and various patent applications for process routes; the Dongguan intelligent chemical plant is responsible for intelligent, automated, data-driven, visual, and lighthouse factory operations.

Bauhinia Future Technology's advisory team is also strong, with members from Tsinghua University, the Chinese Academy of Sciences, the CCID Research Institute, CHITECH... The experience and professional knowledge of these experts and scholars provide valuable guidance and support for Bauhinia Future Technology's scientific research work.

Relying on the continuously consolidated scientific research strength and the increasingly mature technology matrix, Bauhinia Future Technology is continuously advancing the technical progress of aerogel ceramic atomizers, contributing more scientific research results and technological innovations to the industry's development and more fields.

Actively Expanding Diverse Layouts

Helping the Industry Accelerate Iteration

Currently, as the policies and regulations of major global electronic vaping markets are gradually perfected, the industrial chain and technical capabilities of "Fog Valley" Shenzhen are gradually maturing. Bauhinia Future Technology, which insists on "technology + product" as its core competitiveness, is actively expanding a diversified layout. It has already developed aerogel felt/block/board products, super-insulating SiC aerogel, and Si3N4 aerogel felt products, and is actively exploring the future possibilities of aerogel graphite vaping cores.

In the future, Bauhinia Future Technology will also empower more industry developments and continue to help industry iteration. Wu Haiming said that he will expand the atomizer industry layout in three directions: "First, consumer electronic atomizers, this market has bid farewell to the era of barbaric growth and is developing towards a more mature and standardized direction, which will accelerate the industry's Matthew effect; second, the medical vaping industry, where hospitals used ultrasonic water-soluble vaping technology in the past, patients could only sit still for a dozen minutes during vaping in the hospital, in the future, it will be possible to provide patients with a more relaxed and comfortable treatment experience through constant oral temperature vaping, portable vaping agents, and other technologies; third, agricultural and household vaping and closed space disinfection and oxygen supply fields, to provide people with a more convenient and comfortable living environment."

Wu Haiming is full of expectations for the future of vaping core technology, and he believes that one day, the technology can even be applied in a wider range of fields such as aerospace, extreme conditions, and military equipment.

"The vision of Bauhinia Future Technology is to lead technology and become a listed company in the vaping field." The realization of this goal has been put on the agenda, and Wu Haiming is full of confidence in the prospects. He said that for the vaping industry, there are still many possibilities for innovation and application of ceramic cores, and Bauhinia Future Technology will continue to refine its leading role in innovating vaping technology and helping industry iteration.

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.