3D printing, also known as additive manufacturing, is a method of manufacturing physical parts by gradually adding materials. It offers advantages such as rapid prototyping, complex molding, customized manufacturing, reduced assembly, and shortened R&D cycles.

With the advancement and maturity of materials and processes, 3D printing technology is no longer considered "high and out of reach" but is gradually penetrating various industries, including the e-cigarette industry.

The main materials used in 3D printing technology include metals, ceramics, and plastics. Accordingly, in the e-cigarette industry, these materials are used in molds, atomizer cores, and product development.

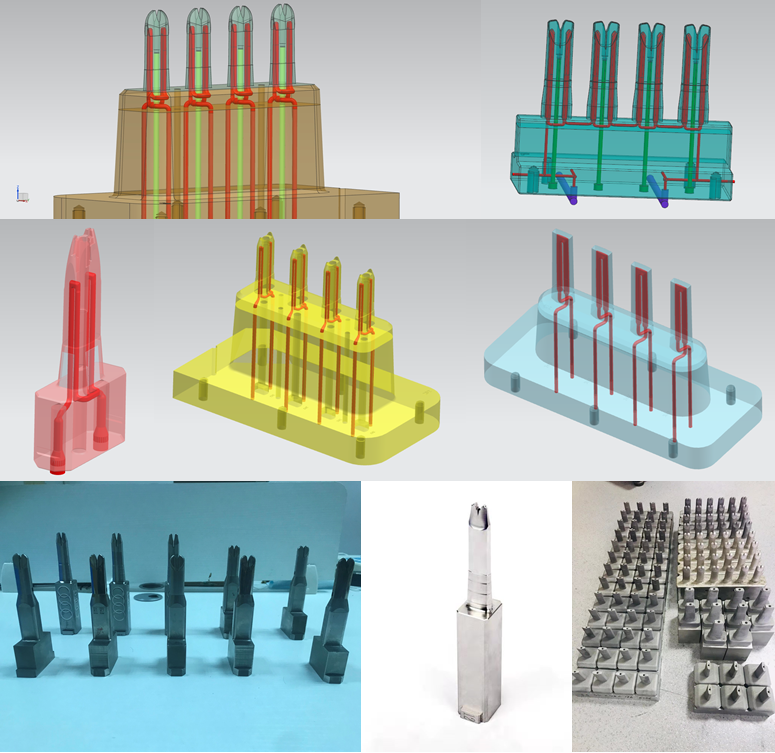

1.3D printed e-cigarette oil cup mold

The materials of electronic cigarette plastic shells are basically high-temperature materials.

- PCTG:260-280℃

- PPSU:370℃

- PC:270-320℃

During the injection molding process, approximately 90% of problems are caused by insufficient mold cooling. High-temperature materials are more susceptible to temperature-related molding problems. Therefore, the design requirements for cooling channels in injection molds for e-cigarette plastic casings are higher than for general products.

E-cigarette plastic casings are deep-cavity molds, and the cross-sectional area of the cavity decreases with increasing depth. This deep-cavity mold is difficult to manufacture using traditional cooling channel processing methods. Typically, cooling wells are simply designed, but due to limited space, the wells are small and shallow within the mold core, making the effect less pronounced.

The design concept behind 3D-printed conformal cooling channels is to tightly adhere the cooling channels to the mold cavity surface, allowing them to adapt to the mold cavity shape. Using 3D-printed conformal cooling channels improves mold cooling efficiency and cooling uniformity.

3D-printed molds can arrange conformal cooling channels based on the mold shape, ensuring adequate cooling balance across the product surface. This significantly addresses issues caused by uneven cooling, improves e-cigarette oil cup production efficiency, significantly increases production capacity, and effectively extends mold life.

Picture Ningbo Craftsmanship

Picture Ningbo Craftsmanship

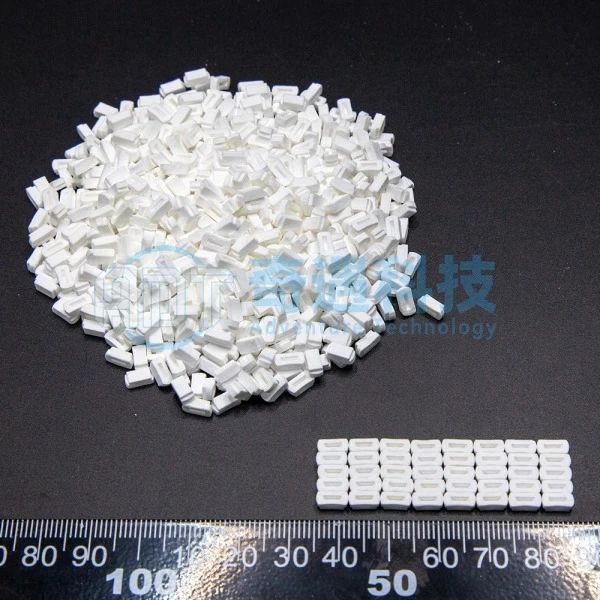

2.3D printed ceramic atomizer core

The Qiyu Technology team has partnered with a leading domestic e-cigarette manufacturer to develop a new application called "ceramic atomizer core + 3D printing." This collaboration is expected to apply high-speed 3D printing technology to the production of e-cigarette atomizer cores, providing a novel solution for atomizer core manufacturers and addressing the pain points of low production efficiency, uncontrolled quality, and material waste associated with ceramic atomizer cores.

Qiyu Technology's 3D printers are equipped with a 4K optical engine with an optical precision of 0.05mm. The atomizer cores they produce achieve a porosity of over 55% and an adjustable pore size of 10-50μm. They can print tens of thousands of atomizer cores per day and can create extremely complex shapes and structures according to design requirements.

3.3D printing shortens product development cycles

The company's tremendous success in the global market stems not only from strong technical capabilities but also from robust design capabilities. E-vapor products share similar characteristics to consumer electronics, skewed towards a younger customer base. In today's increasingly networked and globalized world, consumer preferences are becoming increasingly diverse, and product updates are accelerating.

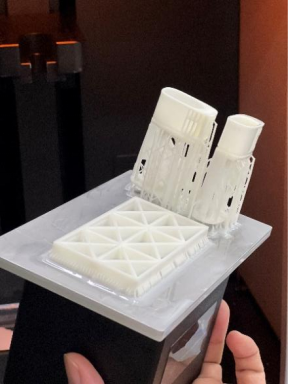

This requires the industrial design department to conduct design and verification with greater efficiency. 3D printing technology, with its rapid response and one-off production capabilities, is an ideal process for product design verification.

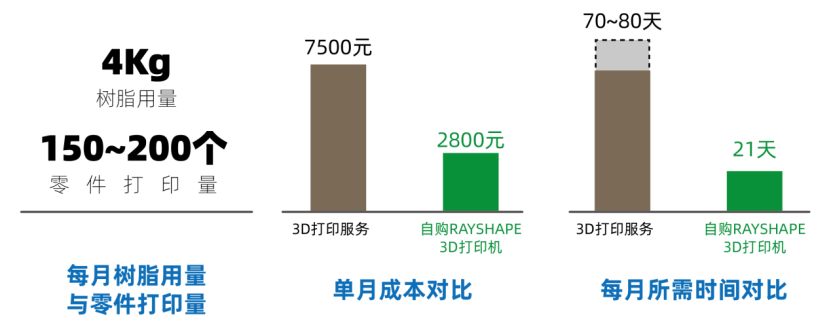

Initially, Kikna used a third-party 3D printing service provider to create product prototypes. This solution significantly shortened the design verification cycle for the ID team.

However, as the number of product SKUs increased and the pace of product updates accelerated, the drawbacks of this approach quickly became apparent. A single print run requiring two to three days became unacceptable.

As the company's scale and industry influence continued to expand, product design became increasingly prominent, and design confidentiality became a key concern. The potential risks of outsourcing 3D printing became increasingly significant.

Based on these factors, the Kikna ID team considered purchasing their own 3D printer. It only takes about 3 hours to print a version of the atomizer shell. Including the time for modifying the drawings, the product design can be iterated twice a day at most.

Atomizer housing printed using Rysai Shape 1 HD

It can be seen that the application of 3D printing technology in the e-cigarette industry has promoted the innovation and development of industry products and technologies to a certain extent.

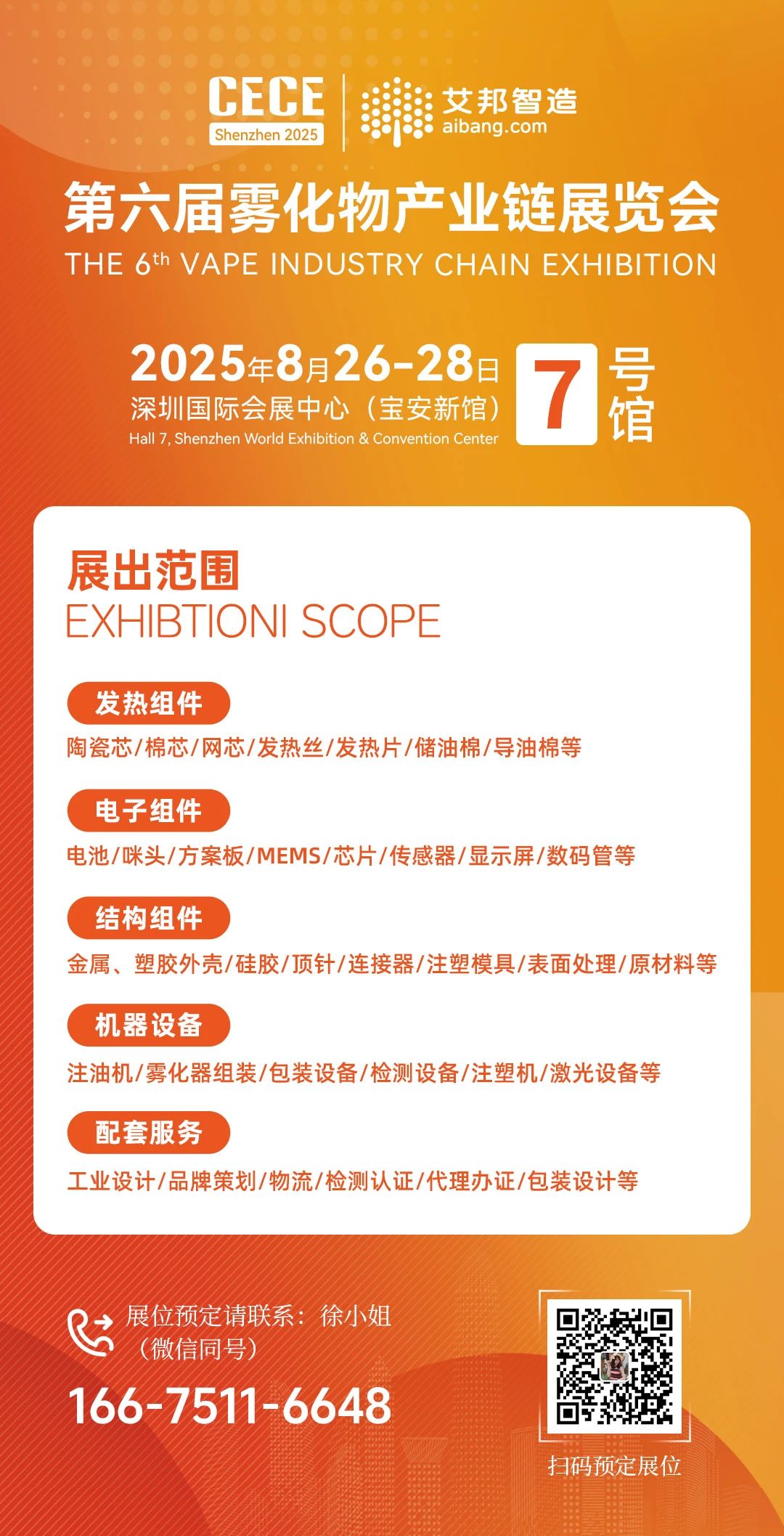

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.