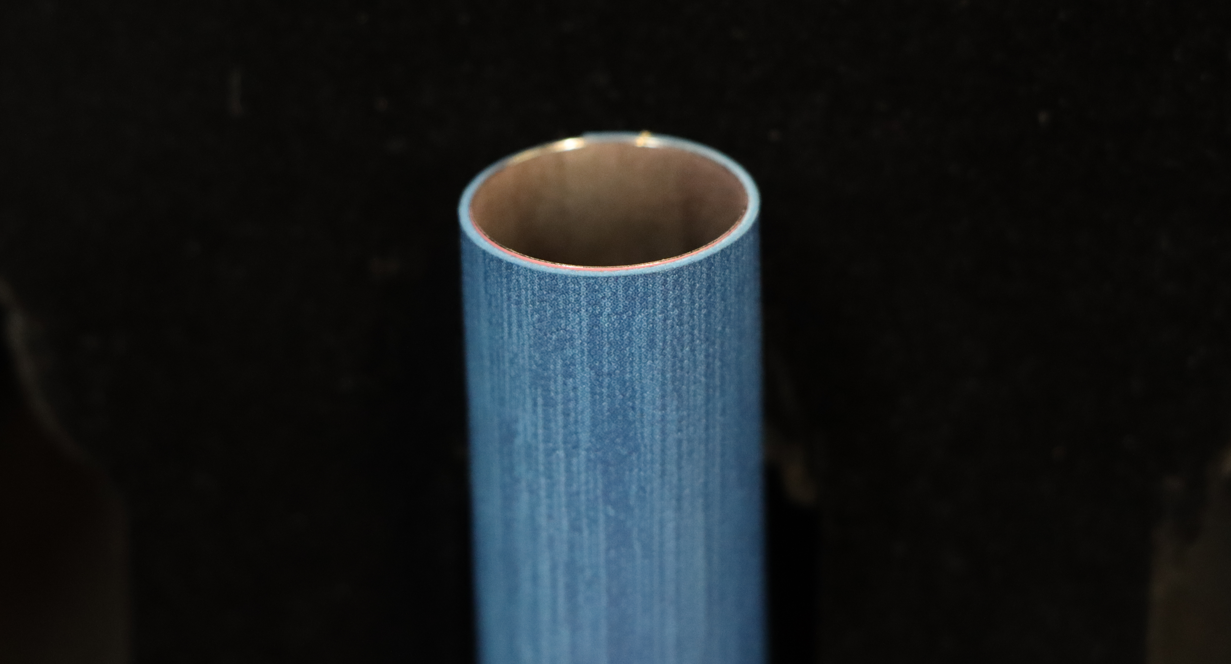

The appearance of the electronic cigarette adopts the skin veneer process, which can present rich leather texture and a warm touch. It is used in high-power electronic cigarettes, cartridge-changing electronic cigarettes, and disposable electronic cigarettes. The most common ones are flat veneer or partial covering, and a few will adopt full covering of the round tube.

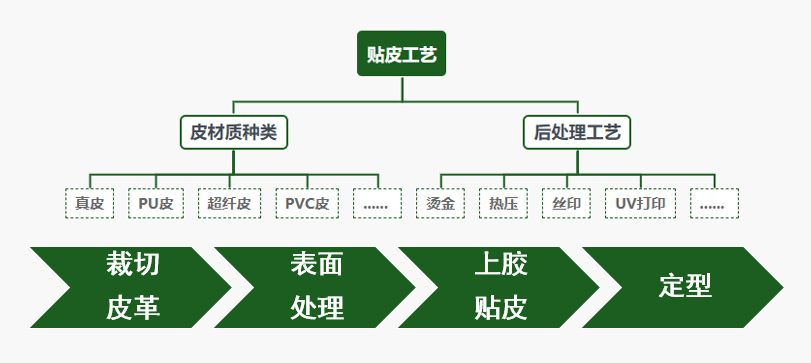

Simple diagram of the lamination process

Simple diagram of the lamination process 看封边一致性

看封边一致性 Check the smoothness of the cut leather

Check the smoothness of the cut leather电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.