As people's quality of life improves, their expectations for product aesthetics and quality are also rising. An increasing number of consumer products are being made of alloy materials. Metal materials convey a sense of luxury, strength, and durability, while traditional plastic housings are increasingly being labeled "cheap" and "low-quality" by consumers.

Physical properties comparison table

Of these four alloys, titanium alloy is the hardest and possesses the highest strength. In terms of hardness, titanium alloy is significantly harder than the other three alloys. In terms of tensile strength, titanium alloy is stronger than zinc alloy, followed by magnesium alloy.

Strength and hardness comparison

When designing product structures, weight is also a consideration. If specific gravity is factored in, zinc alloy, due to its highest density, has the lowest specific strength. Titanium and magnesium alloys have higher specific strengths, but titanium alloys are expensive and have poor workability. Therefore, magnesium alloys are often used when weight and strength are a factor.

The density of aluminum alloy is 2.63~2.85g/cm3, with high strength (σb is 110~270MPa), specific strength close to that of high alloy steel, specific stiffness exceeding that of steel, good casting performance and plastic processing performance, good electrical and thermal conductivity, good corrosion resistance and weldability.

The fluidity of die-cast aluminum alloy is relatively good, and the melting point is 660℃.

Aluminum alloys are also widely used in product structural design, with common processing techniques including die-casting, extrusion, machining, stamping, and forging. Aluminum alloy profiles are widely used in architectural doors and windows, and they are also commonly used in the frames of mechanical equipment. Aluminum alloys are also used in the casings of electronic products and fast-moving consumer goods. These products require a high level of appearance, and common processes include extrusion, machining, and stamping.

Apple's MacBook series uses aluminum alloy CNC one-piece molding body

Die-cast aluminum is rarely used in fast-moving consumer goods casings because die-cast aluminum alloys contain a high content of silicon, which directly reacts with the anodizing agent during anodic oxidation, resulting in a poor surface finish. Aluminum castings are commonly used for internal structural components and parts with minimal aesthetic requirements. Motorcycle engine casings require complex structures that require both low weight and sufficient strength, and are often made from rotary aluminum alloy die-cast blanks.

For the 2–8 series, the last two digits have no special significance and are only used to distinguish different aluminum alloys within the same group. The second digit of the designation indicates the modification status of the original pure aluminum.

- 2-series: Aluminum alloys with copper as the primary alloying element. For example, 2011 is a free-cutting alloy with good machinability and high strength. 2018 and 2218 are forging alloys with good forgeability and relatively high high-temperature strength.

- 3-series: Aluminum alloys with manganese as the primary alloying element. Examples include 3105, which is used in building materials, colored aluminum sheets, and bottle caps.

- 4-series: Aluminum alloys with silicon as the primary alloying element. For instance, 4032 offers good heat resistance and wear resistance, along with a low coefficient of thermal expansion. It is used in pistons and cylinder heads.

- 5-series: Aluminum alloys with magnesium as the primary alloying element. 5052 is one of the most representative medium-strength alloys, commonly used in general sheet metal work, ships, vehicles, buildings, bottle caps, and honeycomb panels.

- 6-series: Aluminum alloys with magnesium as the primary alloying element and strengthened by the Mg₂Si phase. 6063 is a representative extrusion alloy with lower strength than 6061 but excellent extrudability, suitable for forming complex cross-sectional shapes. It also has good corrosion resistance and surface treatment properties, and is used in architecture, highway guardrails, railings, vehicles, furniture, household appliances, and decorative items.

- 7-series: Aluminum alloys with zinc as the primary alloying element. 7075 is one of the aluminum alloys with the highest strength, though it has relatively poor corrosion resistance. Its corrosion resistance can be improved by cladding with 7072, though this increases cost. It is used in aircraft and ski poles.

- 8-series: Aluminum alloys with other elements as the primary alloying elements.

- 9-series: Reserved for future alloy groups.

常用铝合金性能表

Zinc alloys have a low melting point, good fluidity, and are easily welded. Based on the manufacturing process, they can be divided into cast zinc alloys and wrought zinc alloys. Cast zinc alloys offer excellent fluidity and corrosion resistance, making them suitable for die-casting instruments, automotive parts casings, and other applications. Wrought zinc alloys, with their excellent plasticity and ductility, are primarily used in battery casings, printed circuit boards, roofing panels, and household hardware. Cast alloys are produced in much greater quantities than wrought alloys, making wrought alloys rarely used in structural components for fast-moving consumer goods. Therefore, the following discussion focuses solely on die-cast zinc alloys.

Zinc alloy has a density of 6.3-6.7 g/cm² and a tensile strength (σb) of 280-440 MPa. It also has a low melting point, melting at 385°C, making it easy to die-cast.

Zinc alloy has a high specific gravity, the highest of the four alloys discussed in this article, and offers the best fluidity. This gives it excellent casting properties, allowing it to die-cast complex, thin-walled precision parts with smooth surfaces.

At room temperature, zinc alloy exhibits good strength. However, it should be noted that zinc alloys should not be used in high or low-temperature environments (below 0°C). While zinc alloys exhibit good mechanical properties at room temperature, their tensile strength and impact resistance decrease significantly at high temperatures and low temperatures. Zinc alloys also have poor corrosion resistance. When impurities such as lead, cadmium, and tin exceed the specified concentration, castings can age and deform. Zinc alloy die-castings are subject to aging, a phenomenon in which their strength naturally decreases over time, making them brittle. This is why many people complain about zinc alloy faucets breaking when replacing them, leaving the threads stuck in the pipe and unable to be removed. Therefore, Mr. Fang recommends choosing copper faucets over zinc alloys when renovating.

Currently, there are two standard series of alloys used internationally for castings: ZAMAK alloys and the ZA series.

ZAMAK alloys in use include ZAMAK2, ZAMAK3, ZAMAK5, and ZAMAK7. (For simplicity, these alloys are collectively referred to as alloys 2, 3, 5, and 7.)

The ZA series includes ZA-8, ZA-12, ZA-27, and ZA-35. ZA-8 is primarily used for hot-chamber die casting, while ZA-12 and ZA-27, due to their special melting requirements, can only be used for cold-chamber die casting. ZA-35 is generally used for gravity casting. ZAMAK alloys, developed prior to the ZA series, are primarily used for pressure casting. The most widely used is zinc alloy 3.

- ZAMAK 2: Suitable for mechanical parts with special requirements for mechanical properties, high hardness, good wear resistance, and moderate dimensional accuracy.

- ZAMAK 3: Offers excellent fluidity and mechanical properties. Suitable for castings with low mechanical strength requirements, such as toys, lamps, decorative items, and some electrical components.

- ZAMAK 5: Offers good fluidity and good mechanical properties. Suitable for castings with moderate mechanical strength requirements, such as automotive parts, electromechanical components, mechanical parts, and electrical components.

- ZA8: Offers good impact strength and dimensional stability, but has poor fluidity. Suitable for die-casting small workpieces with high precision and mechanical strength requirements, such as electrical components.

- Superloy: Offers optimal fluidity and is suitable for die-casting thin-walled, large, high-precision, and complex-shaped workpieces, such as electrical components and their housings.

Magnesium alloys are alloys based on magnesium with other elements added. The main alloying elements are aluminum, zinc, manganese, cerium, thorium, and small amounts of zirconium or cadmium. Currently, magnesium-aluminum alloys are the most widely used, followed by magnesium-manganese alloys and magnesium-zinc alloys. Due to their excellent properties in casting, extrusion, cutting, and bending, magnesium alloys are widely used in the automotive, electronics, textile, construction, and military sectors.

The melting point of magnesium alloys is 650°C, lower than that of aluminum alloys, and they offer excellent die-casting properties. The tensile strength of magnesium alloy castings is comparable to that of aluminum alloy castings, generally reaching 250 MPa and reaching over 600 MPa.

Magnesium alloys have a low density (approximately 1.8 g/cm³) and high strength. Magnesium alloys are the lightest metal structural materials, with a specific gravity of only 1.8, two-thirds that of aluminum and one-quarter that of iron. Their high specific strength of 133 makes them suitable for use as high-strength materials. High-strength magnesium alloys can even rival the specific strength of titanium.

Magnesium alloys have a high elastic modulus and excellent vibration damping properties. Within their elastic range, magnesium alloys absorb half as much energy as aluminum alloys when subjected to impact loads, resulting in excellent vibration and noise reduction properties.

Magnesium alloys also offer excellent die-casting properties, with wall thicknesses as low as 0.5mm, making them suitable for the manufacture of various automotive die-cast parts. Magnesium alloy parts are highly stable, and die-cast parts can be cast with high dimensional accuracy, allowing for high-precision machining.

Magnesium alloys offer significant advantages over other alloys in heat dissipation. For heat sinks of the same size and shape as those made of magnesium and aluminum alloys, heat (temperature) generated by a heat source is more easily transferred from the base of the fins to the top of the fins in magnesium alloys than in aluminum alloys, resulting in higher temperatures at the top.

However, magnesium alloys have a high coefficient of linear expansion, reaching 25-26 μm/m°C, compared to 23 μm/m°C for aluminum alloys, approximately 20 μm/m°C for brass, 12 μm/m°C for structural steel, and approximately 10 μm/m°C for cast iron. Rocks (such as granite and marble) have a coefficient of linear expansion of only 5-9 μm/m°C, and glass has a coefficient of expansion of 5-11 μm/m°C. When applying magnesium alloys near heat sources, the effects of temperature on structural dimensions must be considered.

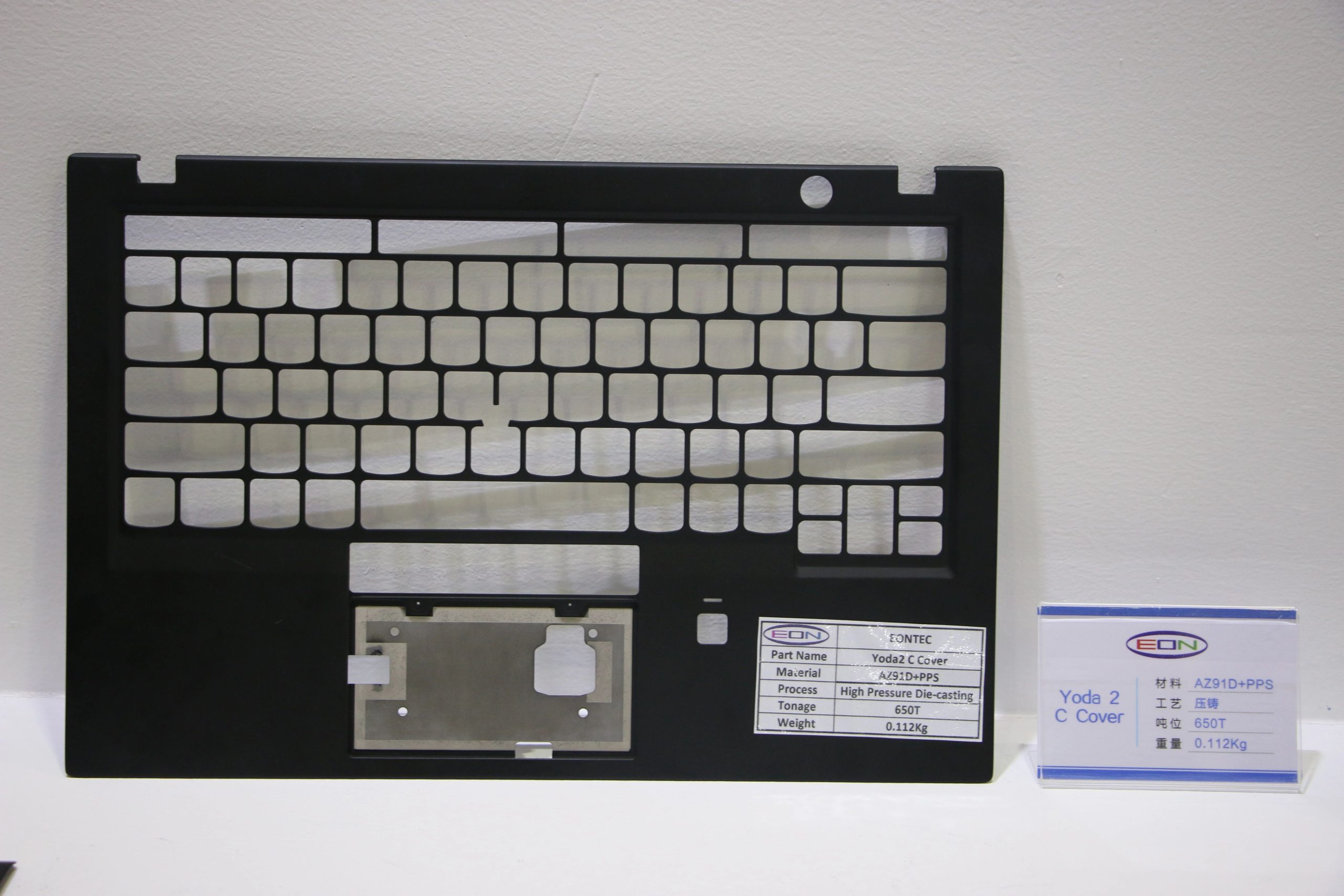

Examples of magnesium alloy applications include: mid-range, high-end, and professional digital SLR cameras, which typically use magnesium alloys for their frames, durability, and pleasant feel; mobile phone and laptop computer housings; and the housings and heat dissipation components of computers and projectors, which generate high temperatures internally. Furthermore, magnesium alloys are used in automotive steering wheels, steering brackets, brake brackets, seat frames, mirror brackets, and distribution brackets, which require lightweight yet high strength.

Figure 1: Magnesium alloy laptop computer C part

According to the forming method, it is divided into two categories: deformed magnesium alloys and cast magnesium alloys.

Magnesium alloy grades are represented by a letter followed by a number and a letter. The first letter represents the element code for the primary alloying element (element codes are specified in the table below), and the following number represents the average of the upper and lower limits of the primary alloying element. The last letter is an identification code, used to identify alloys with different specific elements or slightly different element contents.

Common grades of magnesium alloys are:AZ31B、AZ31S、AZ31T、AZ40M、AZ41M、AZ61A、AZ61M、AZ61S、AZ62M、AZ63B、AZ80A、AZ80M、AZ80S、AZ91D、AM60B、AM50A、M1C、M2M、M2S、ZK61M、ZK61S、ME20M、LZ91、LZ61、LZ121、LA141、LA191、LAZ933、LA81、LA91、LAZ931、MA18、MA21、MA14等。

Titanium alloys refer to a variety of alloys made from titanium and other metals, characterized by high strength, excellent corrosion resistance, and high heat resistance. Titanium alloys are widely used in aircraft engine compressor components, frames, skins, fasteners, and landing gear. They are also used in rockets, missiles, and high-speed aircraft structural components.

Titanium is an allotrope with a melting point of 1668°C. Below 882°C, it adopts a close-packed hexagonal lattice structure, known as α-titanium; above 882°C, it adopts a body-centered cubic lattice structure, known as β-titanium. By utilizing the different characteristics of these two titanium structures and adding appropriate alloying elements, titanium alloys with different microstructures are produced. At room temperature, titanium alloys have three matrix microstructures, resulting in the following three categories: α-alloys, (α+β) alloys, and β-alloys. In my country, these are designated as TA, TC, and TB, respectively.

The density of titanium alloy is generally around 4.51g/cm3, which is only 60% of that of steel. Some high-strength titanium alloys exceed the strength of many alloy structural steels. Therefore, the specific strength (strength/density) of titanium alloy is much greater than that of other metal structural materials, and can be used to produce components with high unit strength, good rigidity and light weight.

部分钛和钛合金的力学性能

钛合金产品

ThinkPad X1 Titanium Yoga 2-in-1 laptop with a titanium chassis

Titanium alloy products can be produced through die casting and machining. Titanium alloys have a very high melting point, requiring high quality mold steel. Numerous machining methods are available for titanium alloys, including turning, milling, boring, drilling, grinding, tapping, sawing, and electro-discharge machining (EDM).

Titanium alloys also exhibit poor machinability. The cutting forces during titanium alloy cutting are only slightly higher than those of steel of similar hardness. However, the thermal conductivity of most titanium alloys is very low, only 1/7 that of steel and 1/16 that of aluminum. Therefore, the heat generated during cutting is not dissipated quickly, but instead accumulates in the cutting area, causing rapid wear and collapse of the tool edge and the formation of built-up edge.

Article | Aluminum rubbing, aluminum deep processing, Zhihu Fang Gong Rich, Material Notes, Titanium Valley Voice

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.