Low-residue oil-absorbing cotton emerges as a focal point of development within the industry.

Amid the fierce competition in the atomization industry, there is an ongoing quest for materials that boast lower residue rates and higher fidelity of reproduction. Against this backdrop, the integral role of cotton as a pivotal component in the realm of atomization is increasingly underscored. Commencing with its original mission to prevent oil leakage, the focus has gradually shifted over time and through successive product iterations, with a growing number of manufacturers prioritizing the enhancement of cotton's low-residue performance and the improvement of the user's sensory experience.

Unveiling the Dynamics of E-liquid Transmission within Oil-Absorbing Cotton

As elucidated by Professor Huang's team at Donghua University, the interaction between the integrated oil-absorbing cotton and e-liquid mirrors the transmission of water within fibrous textiles.

Although the composition of e-liquid is relatively complex, its primary constituents, PG/VG, like water, are polar molecules, rendering water an applicable analogy for reference purposes.

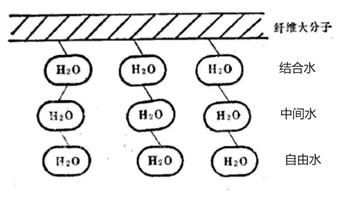

Given the diversity in the structure and chemical composition of fibers within the fabric, their interaction with water molecules varies, leading to the absorption of water being categorized into three parts: bound water, intermediate water, and free water, as depicted below.

Similarly, upon absorbing e-liquid, the integrated cotton wick will also form bound oil, intermediate oil, and free oil.

During the vaporization process of electronic cigarettes, if certain constituents of the e-liquid form exceedingly tight "bound oil" and "intermediate oil" through hydrogen bonds or intermolecular forces with the fibers, it results in impaired e-liquid delivery, leading to issues of high residue and low fidelity.

The transmission of e-liquid within the integrated cotton primarily comprises two components:

-

One portion moves downward, i.e., along the axis of the fibers, fundamentally relying on capillary action, and since synthetic fibers generally lack pores, transfer mainly occurs through the narrow gaps formed between fibers. Within a certain range, the greater the number of fibers per unit area, the stronger the capillary effect.

-

The other portion moves from the exterior inward, constituting nonlinear diffusion, wherein during the process of vaping, the e-liquid diffuses from the high-concentration integrated cotton to the lower-concentration wicking cotton.

Enhancing the performance of the oil-absorbing cotton can be achieved by employing varying gradient densities.

Professor Huang's team from Donghua University discovered that through the implementation of gradient density structural design, the integrated cotton could achieve a more efficient e-liquid conduction capability, facilitating the smooth export of free oil and even some intermediate oils, ultimately addressing the issue of residual rates.

Under the guidance of Professor Huang's doctoral team, a leading entity within the nation's elite "Double First Class" textile colleges at Donghua University, the development of the integrated cotton involved multifaceted approaches including design, mold modification, and equipment overhaul. The culmination of these efforts was the successful creation of integrated cotton products featuring various gradient densities, for which multiple related patents were filed, as illustrated below.

据悉,该产品目前已经在深圳千格维投放市场,该产品在保证锁油不漏油的情况下,残留进一步减低,比现有市面上产品提高30%-50%不等。

1、残油率小口径11ML剩余最低至5%,大口径18ML剩余最低至12%残油。

2、孔隙率最高达到97%,密度常规可做0.06-0.065-0.075,非常规定制0.05-0.1密度

3、 高效导油速率,吸水率是棉(克重)的14倍

该产品在保证不漏油的基础上能做到如上技术,完美解决各品牌厂商的研发系列痛点。

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.