Summary:

This article is part of the series exploring the secrets of e-cigarette flavor, focusing on "Aerosol Edition." It discusses the factors that form the flavor of electronic cigarettes. The key to flavor lies in the formation, evolution, and transport of aerosols, which include processes such as nucleation, condensation, evaporation, and coagulation. The article also explains that electronic cigarette aerosols are mainly composed of tiny particles and liquid particles. This content helps to deepen the understanding of the mechanism behind the formation of e-cigarette flavors.

随着新型雾化行业的快速发展,用户对电子烟的要求早已摆脱了“冒烟即可”的阶段,当今用户追求高还原度、高满足感、抽吸饱满柔顺的电子烟产品。因此,口感成为判断电子烟优劣的最终标准,那么口感又究竟受什么因素影响呢?

本专题将从机理出发,带您探秘影响电子烟口感形成的各个因素,以此加深对口感形成机制的了解。

Topic 1 气溶胶的形成、演变及输送

首先我们介绍一个概念,气溶胶是指悬浮在气体介质中的固态或液态颗粒所组成的气态分散系统。传统卷烟的烟气是烟丝燃烧产生的固体颗粒,电子烟烟气是雾化液经蒸发冷凝后形成的液体颗粒,二者悬浮在空气介质中形成气溶胶,但是二者形成机制不同,研究方法也不同。

(1)气溶胶的形成及演变

成核:在仅由蒸气组成的混合物中,一种或多种化学组分可能处于过饱和状态,这意味着分压大于混合物的平衡蒸气压。从能量上讲,有利于蒸气分子重组成液相。如果过饱和度足够高,则可以克服与液滴表面的形成相关联的能垒,从而导致液滴成核;

冷凝蒸发:蒸汽分子更容易改变相并冷凝到已经存在的表面上。该过程由蒸汽的饱和度以及蒸汽分子相对于混合物的流动性驱动。如果蒸汽变得不饱和,气溶胶液滴可能开始蒸发并消失;

聚合破碎:在稠密的气溶胶中,粒子可能会相互碰撞。伴随着这些碰撞事件,两个粒子有可能合二为一;它们聚合。相反,也存在粒子被散射成多个粒子的概率,即粒子分裂;

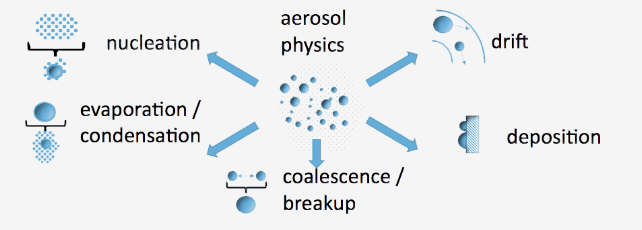

图一 气溶胶的形成演变及输送现象示意图

图一 气溶胶的形成演变及输送现象示意图

(https://www.intervals.science/resources/aerosolved)

(2)气溶胶的输送

漂移:颗粒具有与载气不同的性质,例如,密度或粘度,这可能导致颗粒相的运动偏离载气的运动。这种运动可以由惯性引起,例如,当液滴携带太多的动量而不能足够快地适应由载气感受到的局部加速度时。

扩散:当颗粒足够小时,这种布朗运动导致液滴的扩散。从宏观的角度来看,这种扩散就像“规则”的分子扩散,使得气溶胶很快看起来更分散。

沉积:载气在这个表面的速度为零,这意味着没有气体分子可以穿过表面。如果气溶胶粒子精确地跟随载气的流线,它们的运动也会在表面停滞,从而阻止沉积。然而,气溶胶漂移和扩散可能引起偏离载体流线的颗粒的净输送。因此,漂移和扩散都是使气溶胶沉积的机制,并且在这个意义上,沉积可以被视为气溶胶的分散特性的结果。

由此,我们可以推断电子烟气溶胶主要由两部分构成:

1 雾化液表面在受热的状态下,未达到蒸发的温度时,突破液体表面张力的束缚而脱离液体表面的微小颗粒(扩散)

2 雾化液受热,达到蒸发温度后,高温的蒸气遇到常温气流发生冷凝而产生的液态颗粒(蒸发冷凝)

电子烟气溶胶生成过程详见Exploring the Working Principle of Vapor-Type Electronic Cigarettes

With the rapid development of the new atomization industry, users' expectations for electronic cigarettes have gone beyond the simple "smoke-producing" stage. Today's users seek high-fidelity, satisfying, and smooth vaping experiences from electronic cigarette products. Therefore, the flavor has become the ultimate standard for judging the quality of electronic cigarettes. But what factors influence the flavor?

This series will start from the mechanism, guiding you through the various factors that affect the formation of electronic cigarette flavor, to deepen your understanding of the flavor formation mechanism.

Topic 1: Formation, Evolution, and Transport of Aerosols

First, let's introduce a concept. An aerosol refers to a gaseous dispersion system composed of solid or liquid particles suspended in a gaseous medium. The smoke from traditional cigarettes is made up of solid particles produced by the combustion of tobacco, while the vapor from electronic cigarettes is made up of liquid particles formed by the evaporation and condensation of the e-liquid. Both are suspended in the air medium to form aerosols, but their formation mechanisms and research methods are different.

(1) Formation and Evolution of Aerosols

Nucleation: In a mixture composed only of vapor, one or more chemical components may be in a supersaturated state, meaning that the partial pressure is greater than the equilibrium vapor pressure of the mixture. Energetically, this is conducive to the recombination of vapor molecules into a liquid phase. If the degree of supersaturation is high enough, it can overcome the energy barrier associated with the formation of a liquid droplet surface, leading to droplet nucleation.

Condensation and Evaporation: Vapor molecules are more likely to change phase and condense onto existing surfaces. This process is driven by the saturation of the vapor and the mobility of the vapor molecules relative to the mixture. If the vapor becomes unsaturated, aerosol droplets may begin to evaporate and disappear.

Coagulation and Fragmentation: In dense aerosols, particles may collide with each other. With these collision events, two particles may combine; they coagulate. Conversely, there is also a probability that particles will be scattered into multiple particles, i.e., fragmentation.

Figure 1: Schematic Diagram of Aerosol Formation, Evolution, and Transport Phenomena

(https://www.intervals.science/resources/aerosolved)

(2) Transport of Aerosols

Drift: Particles have different properties from the carrier gas, such as density or viscosity, which may cause the particle phase to deviate from the movement of the carrier gas. This movement can be caused by inertia, for example, when droplets carry too much momentum to quickly adapt to local accelerations experienced by the carrier gas.

Diffusion: When particles are small enough, this Brownian motion leads to the diffusion of droplets. From a macroscopic perspective, this diffusion is like "regular" molecular diffusion, making the aerosol appear more dispersed quickly.

Deposition: The speed of the carrier gas at this surface is zero, which means that no gas molecules can pass through the surface. If aerosol particles precisely follow the flow lines of the carrier gas, their movement will also stagnate at the surface, thus preventing deposition. However, aerosol drift and diffusion may cause net transport of particles that deviate from the carrier flow lines. Therefore, both drift and diffusion are mechanisms that cause aerosol deposition, and in this sense, deposition can be seen as a result of the dispersal characteristics of the aerosol.

From this, we can infer that the aerosol of electronic cigarettes is mainly composed of two parts:

-

Tiny particles that break free from the surface of the e-liquid due to the heat before reaching the evaporation temperature (diffusion).

-

Liquid particles formed when the heated e-liquid reaches the evaporation temperature, and the high-temperature vapor encounters the normal temperature airflow and condenses (evaporation and condensation).

For a detailed process of electronic cigarette aerosol generation, see Exploring the Working Principle of Vapor-Type Electronic Cigarettes.

In this issue, we have learned together about the formation, evolution, and transport mechanisms of aerosols, as well as the composition of electronic cigarette aerosols.

In the next issue, we have prepared the topic "Study on the Deposition Pattern of Aerosols."

本期与大家一起了解了气溶胶的形成演变及输送机制,以及电子烟气溶胶的构成

下一期我们准备了“气溶胶沉积规律研究”话题

原创产品,制作不易,转载请注明出处。感谢各位的订阅和支持!

越多点赞,越多订阅,越多优质内容~~ 欢迎催更!!

原文始发于微信公众号(雾化探秘):"Exploring the Mouthfeel of Electronic Cigarettes: Aerosol Insights (Part One)."

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.