As a new tobacco product, electronic cigarettes have experienced rapid growth in recent years. Their working principle is roughly as follows: an electronic cigarette atomizer uses an electric heating wire to heat a capillary oil guide rope. The ends of the oil guide rope come into contact with the oil, which is then transported to the electric heating zone under capillary force, where it is heated and vaporized, producing smoke that is then delivered to the consumer.

Model of Heat and Mass Transfer in E-Cigarette Lifts

1. Physical Model

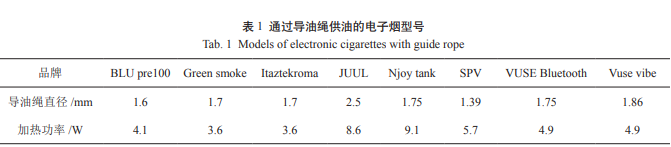

The liquid wick is a core component of the e-cigarette atomizer. Many mainstream e-cigarettes on the market use it to supply liquid. The liquid wick's primary function is to generate capillary forces within its microporous structure to transfer the liquid to the heating wire for heating and atomization. See Table 1 for details.

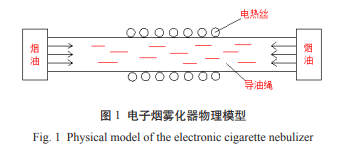

The physical model of the electronic cigarette atomizer studied in this article mainly includes the smoke oil, oil guide rope, etc., as shown in Figure 1:

2. Mathematical Model

Heat Transfer within the Rope:

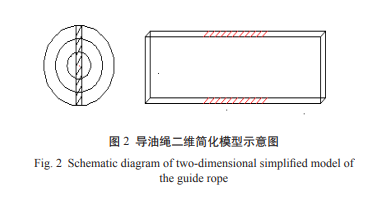

The rope is cylindrical in shape. Because the temperature and liquid concentration fields are uniformly distributed along the circumference, a two-dimensional thin slice along the axial line of the rope is used for modeling. See Figure 2 for details.

Mass Transfer in the Oil Rope:

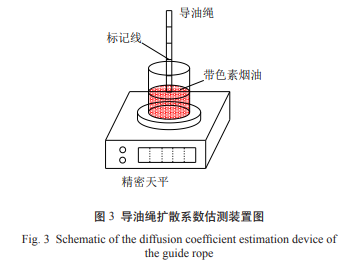

To determine the diffusion coefficient of the liquid in the oil rope, an experimental setup (with a precision balance) was used to estimate the diffusion coefficient according to Fick's law. See Figure 3 for details.

Integration of Simulation Software and Mathematical Model Solution Method

The numerical simulation was implemented using Visual Basic (VB) programming. The physical model was simplified and a structured mesh was used. Due to the simplicity of the structure, mesh independence verification was omitted. This study primarily focused on the unsteady transport of liquid within the wick and did not include the condensation of gas after phase change. Therefore, the outlet region is not indicated in the figure. Based on the above mathematical model and related solution methods, simulation software was designed using VB. The software interface is shown in Figure 4:

Through modeling and analysis of the heat and mass transfer processes within the wick of an e-cigarette atomizer, the following conclusions were drawn:

- The mathematical model of heat and mass transfer developed in this paper for e-cigarette atomizers reveals the temporal variations of the temperature field and e-liquid concentration field within the wick, demonstrating a certain degree of accuracy and reliability.

- Under appropriate conditions, the maximum radial temperature gradient and concentration gradient within the wick exhibit an approximately quadratic function relationship over time; the amount of liquid vaporization exhibits an approximately linear relationship with heating time; and the amount of liquid vaporization increases with increasing heating power.

- Heating power and the diffusion coefficient are two important factors influencing the dry-burning of the wick. Under appropriate conditions, the dry-burning time decreases approximately exponentially with increasing heating power and logarithmically with increasing diffusion coefficient.

来源:《电子烟导油绳内传热传质规律的数值分析》,佟振鸣

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.