电子烟烟雾的视觉感受与粒径测试方法

Visual Perception of Electronic Cigarette Smoke and Particle Size Testing Methods

本文讨论了电子烟烟雾的视觉感受与粒径测试方法。视觉上,电子烟烟雾的颜色和成团性影响用户的视觉体验,其背后的物理原理分别是瑞利散射和米氏散射。烟雾的视觉感受与气溶胶的粒径大小有关,粒径小则呈现蓝色,粒径大则呈现白色。粒径的测试方法主要有激光粒度仪和扫描电迁移率粒径谱仪,各有优缺点,研究人员可根据需要选择合适的测试方法。当前电子烟气溶胶测试面临的主要问题是粒径失真,这与气溶胶成分的捕捉困难和实验环境条件的不稳定有关。

This article discusses the visual perception of electronic cigarette smoke and methods for measuring particle size. Visually, the color and clustering of the smoke affect the user's visual experience, which is based on the physical principles of Rayleigh scattering and Mie scattering. The visual perception of the smoke is related to the size of aerosol particles; smaller particles appear blue, while larger particles appear white. The main methods for particle size testing are the laser diffraction particle size analyzer and the scanning mobility particle size spectrometer, each with its advantages and disadvantages. Researchers can choose the appropriate method based on their needs. The main issue currently faced in the testing of electronic cigarette aerosols is particle size distortion, which is related to the difficulty in capturing certain key components of the aerosols and the instability of experimental environmental

用户在使用电子烟时,非常关注“烟雾量”的多少,既要获得视觉上满足,又要得到实际抽吸时的满足,那么视觉和实际“烟雾量”到底有什么区别,又对应着哪些不同的研究方法呢?

谈到实际“烟雾量”,不得不提一个关键指标—TPM(Total Particulate Matter,指烟气中颗粒物总含量),针对TPM的通用检测方法就是"失重法",测试抽吸前后设备的质量差,作为该设备的TPM值。TPM受设备雾化效率的影响,具体影响机制见探秘蒸汽型电子烟工作原理,同时TPM对抽吸时的口感影响巨大,影响机制请参考电子烟口感探秘之气溶胶篇(三):气溶胶运动、沉积特点与感官体验。

本期主要针对电子烟烟雾的视觉感受与粒径测试方法展开讨论。

电子烟烟雾的视觉体验与粒径测试方法

(1)气溶胶视觉感受

首先我们列举电子烟烟雾的两种视觉表现,1是当我们从电子烟底部吹气或者轻轻抽吸时,烟雾颜色会比较淡,甚至呈蓝色,视觉体验差,如图1所示;2是当我们完整抽吸后吐出来的烟雾,成团性更好,基本呈白色,视觉体验好,如图2所示。那么不同烟雾所呈现的蓝色或白色的原因是什么呢?

图1 蓝色烟雾

图2 白色烟雾

1 蓝色烟雾的成因

瑞利散射:散射强度与光线波长的四次方成反比 ,波长越短,散射越强。通俗来讲粒子的直径远小于入射波的波长,上界大约是波长的1/10(1-300 nm),而短波中又以蓝光能量最大,因此视觉上烟气会呈蓝色,颗粒粒径越小,蓝色越明显。

2 白色烟雾的成因

米氏散射:当大气中粒子的直径与辐射的波长相当时发生的散射,散射强度与频率的二次方成正比;当颗粒粒径大于可见光波长(0.38~0.78μm)时,散射的强度与波长无关,因此烟气视觉上呈现白色,颗粒粒径越大,白色越明显。

(2)电子烟雾气溶胶粒径测试方法

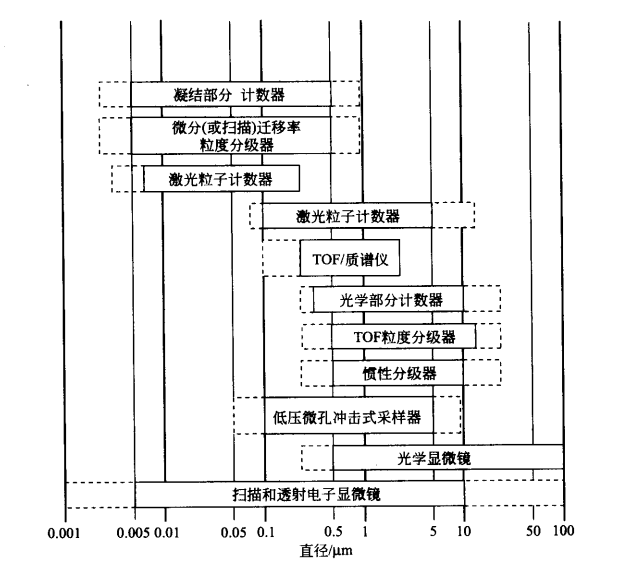

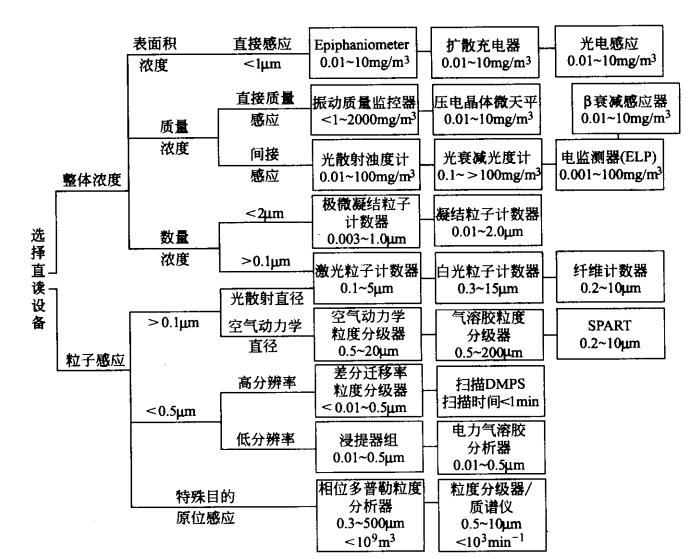

普遍使用的2种气溶胶测量方法分别是收集和分析、直读感应器。两种方法并没有严格的区别,前者能进行完成完整的的浓度测量,定性定量测量气溶胶,但耗费的时间较长;后者能够给出接近于实时的粒径分布信息,但费用更昂贵。图3为几种常用仪器类型的粒径范围,图4为部分仪器的应用流程图。

图3 气溶胶分级和分析设备(Pui: 1996)

图4 选择气溶胶粒子分析直读仪器流程图(Pui: 1996)

目前电子烟行业采用2种粒径测试方法

1 激光粒度仪:利用光散射原理测量颗粒尺寸及分布。粒径测试范围广,但是由于颗粒之间相互影响,准确度稍差。

2 扫描电迁移率粒径谱仪:利用不同尺寸的粒子在电场中的迁移能力不同这一原理,实现粒径测试,测量准确度高,但是只能测试1μm以下的超细颗粒。

两种测量方式各有优缺点,研究人员可根据自身需要进行选择。目前电子烟气溶胶测试的主要问题还是粒径失真,一方面气溶胶中的某些关键成分难以捕捉和收集,另一方面实验的环境条件无法保证气溶胶的稳定,例如气溶胶在输送过程中温度改变导致的冷凝,不同颗粒间的碰撞聚合等。

When using electronic cigarettes, users pay close attention to the amount of "smoke" produced, seeking both visual satisfaction and a satisfying actual inhalation experience. So, what is the difference between visual and actual "smoke" volume, and what different research methods correspond to them?

Talking about the actual "smoke" volume, we must mention a key indicator—TPM (Total Particulate Matter), which refers to the total content of particulate matter in the smoke. The universal testing method for TPM is the "gravimetric method," which tests the mass difference of the device before and after inhalation as the TPM value of the device. TPM is influenced by the atomization efficiency of the device, for which the specific influence mechanism is discussed in the exploration of the working principles of vapor-type electronic cigarettes. TPM also has a significant impact on the mouthfeel during inhalation, with the influence mechanism detailed in "Secrets of Electronic Cigarette Flavor: The Aerosol Chapter (Part Three): Movement, Deposition Characteristics of Aerosols and Sensory Experience."

This issue mainly focuses on the visual perception and particle size testing methods of electronic cigarette smoke.

Electronic Cigarette Smoke Visual Experience and Particle Size Testing Methods

(1) Aerosol Visual Perception

First, let's list two visual representations of electronic cigarette smoke: 1) When we blow from the bottom of the electronic cigarette or gently inhale, the smoke color is lighter, even blue, providing a poor visual experience, as shown in Figure 1; 2) When we exhale the smoke after a complete inhalation, the smoke is better clustered and generally white, providing a good visual experience, as shown in Figure 2. What are the reasons for the different colors, blue or white, presented by different smokes?

Figure 1 Blue Smoke

Figure 2 White Smoke

1 Cause of Blue Smoke

Rayleigh Scattering: The scattering intensity is inversely proportional to the fourth power of the wavelength of light; the shorter the wavelength, the stronger the scattering. Simply put, the diameter of the particles is much smaller than the wavelength of the incident wave, with the upper limit being about 1/10 of the wavelength (1-300 nm). Among short waves, blue light has the most energy, so visually, the smoke appears blue. The smaller the particle size, the more apparent the blue color.

2 Cause of White Smoke

Mie Scattering: Scattering that occurs when the diameter of particles in the atmosphere is comparable to the wavelength of radiation, the scattering intensity is directly proportional to the square of the frequency. When the particle size is larger than the wavelength of visible light (0.38~0.78μm), the intensity of scattering is independent of the wavelength, so the smoke visually appears white. The larger the particle size, the more apparent the white color.

(2) Electronic Cigarette Aerosol Particle Size Testing Methods

Two commonly used aerosol measurement methods are collection and analysis, and direct-reading sensors. There is no strict distinction between the two methods; the former can perform complete concentration measurements, qualitatively and quantitatively measure aerosols, but takes a longer time; the latter can provide near-real-time particle size distribution information, but is more expensive. Figure 3 shows the particle size range of several common types of instruments, and Figure 4 shows the application flowchart for some instruments.

Figure 3 Aerosol Grading and Analysis Equipment (Pui: 1996)

Figure 4 Flowchart for Selecting Aerosol Particle Analysis Direct-Reading Instruments (Pui: 1996)

Currently, the electronic cigarette industry uses two particle size testing methods:

1 Laser Particle Size Analyzer: Measures particle size and distribution based on the principle of light scattering. The particle size testing range is wide, but due to the mutual influence between particles, the accuracy is slightly poor.

2 Scanning Mobility Particle Size Spectrometer: Uses the principle that particles of different sizes have different migration abilities in an electric field to achieve particle size testing. It has high measurement accuracy but can only test ultrafine particles below 1μm.

Both measurement methods have their advantages and disadvantages, and researchers can choose according to their needs. The main problem currently faced in electronic cigarette aerosol testing is particle size distortion, due in part to the difficulty of capturing and collecting certain key components of the aerosols, and also to the inability to ensure the stability of aerosols under experimental conditions, such as condensation caused by temperature changes during aerosol transport, and the collision and agglomeration of different particles.

本期与大家一起了解了电子烟烟雾的视觉感受与粒径测试方法的相关内容,欢迎后台留言或添加小编微信进行合作交流!

原创产品,制作不易,转载请注明出处。感谢各位的订阅和支持!

越多点赞,越多订阅,越多优质内容~~ 欢迎催更!!

原文始发于微信公众号(雾化探秘):电子烟烟雾的视觉感受与粒径测试方法

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.