Ice flower paint, also known as crackle paint or crystal grain paint, is a surface treatment technique that creates cracks through the interaction of resin shrinkage and pigment during the paint curing process.

For aluminum alloys, there are various technical approaches to achieving the ice flower/ice crackle effect, including spraying ice flower paint, laser engraving, chemical etching, and electroplating. Considering factors such as cost and technical maturity, spraying ice flower paint is the easiest method to achieve the ice flower texture on aluminum alloy e-cigarette casings.

I. Spray Painting Techniques for Creating an Ice Flower Effect

1.Special Paint Selection:

- To achieve an ice flower effect, you first need to choose a special-effect paint, such as one containing metallic particles (such as aluminum flakes). After spraying, these metallic particles create a unique shimmering effect within the paint film. Combined with specific spraying techniques, you can simulate the texture of ice flowers.

2.Spraying Techniques and Techniques:

- The spraying process requires certain techniques and skills, such as controlling the spray gun's spray distance, angle, speed, and paint dilution ratio. By adjusting these parameters, you can create a distinct, layered ice flower texture on the aluminum alloy surface.

3.Multi-Layer Spraying and Effect Overlay:

- To achieve a more realistic ice flower effect, you can use a multi-layer spraying technique. First, apply a base coat. After drying, apply a layer of special-effect paint containing metallic particles. By adjusting the color and glossiness of the two coats, you can further enhance the three-dimensionality and layered effect of the ice flower effect.

4.Combining Other Techniques:

- In addition to simply spray painting, other techniques can be combined to achieve the ice effect. For example, prior to painting, the aluminum alloy surface can be treated with special treatments (such as anodizing or frosting) to alter its surface roughness and glossiness. Alternatively, polishing or sanding can be performed after painting to further enhance the texture and aesthetics of the ice effect.

II. Principles of Ice Paint Technology

Depending on the solvent, ice paint, or crackle paint, is divided into oil-based (solvent-based) and water-based.

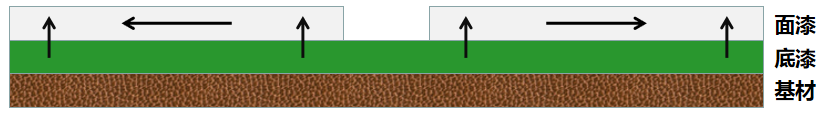

Traditional solvent-based crackle paint is a nitrocellulose crackle paint, which is made by grinding nitrocellulose, pigments, extenders, organic solvents, and additives. Its application principle is to exploit the fact that the nitrocellulose basecoat shrinks more than the topcoat during drying, causing the topcoat to break into pieces, creating various cracks, including the ice effect.

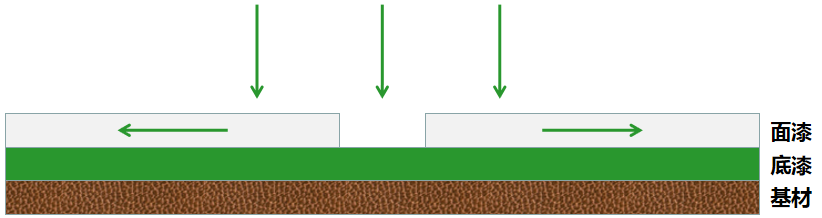

The basic principle of water-based crackle paint is similar to that of solvent-based crackle paint. It also uses the stress difference caused by the different shrinkage degrees of primer and topcoat in the later drying process to pull the surface-dried topcoat to form cracks. The key lies in the timing of the construction process.

Factors influencing the process include the tensile stress caused by shrinkage, the tensile strength of the topcoat film, and the flow properties of the primer.

Under the influence of a flexible primer, the topcoat shrinks unevenly, resulting in stress concentration. When this stress exceeds the tensile strength of the coating, cracking and fissures form.

If the primer is inflexible, the topcoat will not experience stress concentration and generally will not crack. Even when the stress caused by shrinkage is less than or equal to the tensile strength of the coating, cracking will not occur.

In summary, ice flower paints are available in both traditional oil-based solvents and more environmentally friendly water-based versions. Choosing the right type of ice flower paint can be based on specific needs and environmental requirements.

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.