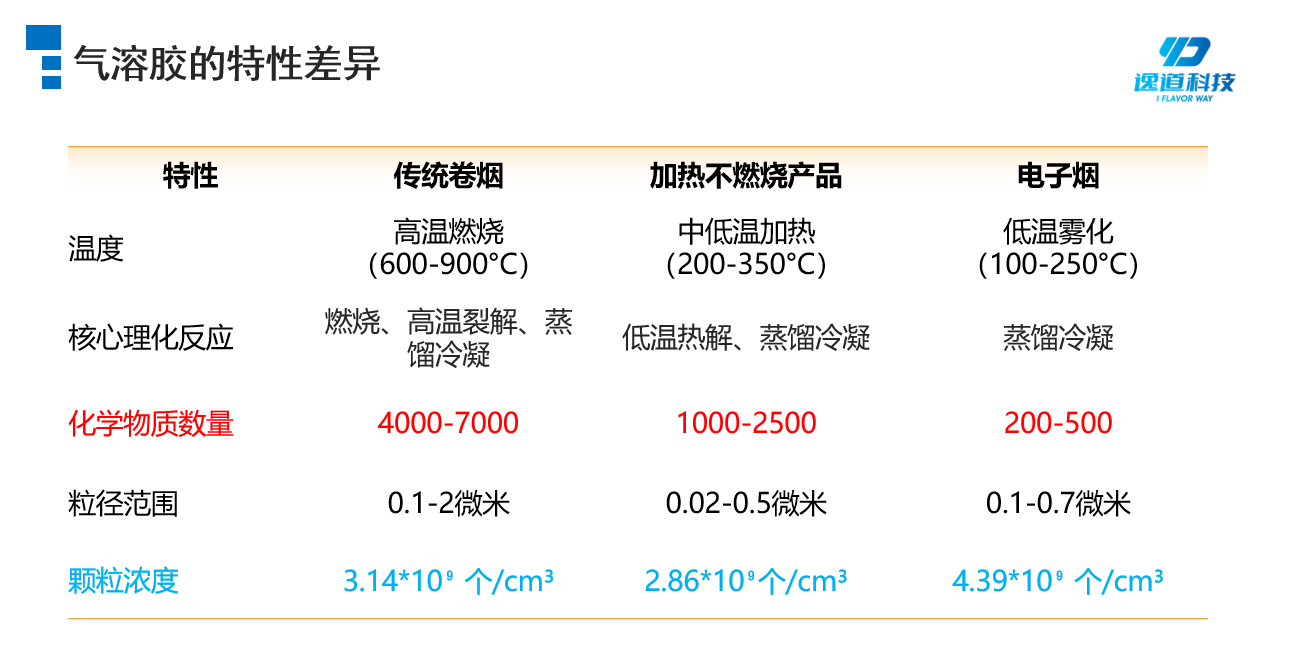

Tobacco aerosol refers to the mixture of tiny particles and droplets suspended in the air produced during tobacco product use. It is the primary carrier for nicotine, flavor components, and harmful chemicals to enter the human body or the environment. Aerosol formation is closely related to the combustion, heating, or atomization process of tobacco products, and the aerosol properties of different tobacco products vary significantly.

HNB uses precisely controlled temperatures (typically 200–350°C) to thermally decompose and vaporize volatile components in tobacco or plant materials, forming an inhalable aerosol. This aerosol consists of the following components:

- Nicotine: released from the tobacco in its free base or protonated form;

- Water vapor: evaporated glycerin (VG) and propylene glycol (PG) added to the tobacco or cartridge;;

- Volatile organic compounds (VOCs): such as aldehydes and ketones (significantly reduced compared to combustion products);

- Tobacco flavorings: natural or artificial flavorings (such as menthol and plant extracts);

- Particulate phase: Nano- to micron-sized particles composed of condensed organic matter and water

I. Key Steps in HNB Aerosol Formation

1. Heating and Mass Transfer Process

Temperature Gradient Control: The heating element heats the tobacco to the target temperature, gradually releasing nicotine, moisture, and volatile compounds from the tobacco.

Mass Transfer Path: Heat is transferred to the interior of the tobacco smoke segment through conduction or convection, disrupting the cell wall structure and releasing internal components (such as nicotine and glycoside-bound flavor precursors in the cell sap).

The heat transfer method and efficiency during the mass transfer process affect the release rate and uniformity of internal tobacco components, and thus the composition and properties of the aerosol.

2. Component Evaporation and Phase Change

Low-boiling-point substances evaporate preferentially: Propylene glycol (PG, boiling point 188°C) and glycerol (VG, boiling point 290°C) evaporate during the initial heating phase, forming the aerosol carrier.

Nicotine Release: Nicotine (boiling point 247°C) dissociates from the tobacco matrix above 200°C and mixes with PG/VG to form the aerosol.

Flavor Precursor Decomposition: Some glycosides (such as cellulose-bound flavor molecules) decompose at high temperatures, releasing volatile aroma components.

The evaporation and phase change processes determine the composition and properties of the aerosol.

3. Aerosol Condensation and Stabilization

Rapid Cooling: After leaving the heating zone, the volatile vapor rapidly condenses upon encountering cool air, forming submicron droplets (the aerosol core).

Particle Growth: PG/VG acts as a "solvent" to encapsulate nicotine and flavor molecules, forming stable aerosol particles (with a particle size distribution concentrated between 0.5 and 2 μm) through Ostwald ripening.

By optimizing the cooling rate and environmental conditions, the aerosol particle size distribution can be controlled, improving its stability and delivery efficiency.

II. Key Factors Affecting Aerosol Properties

1. Temperature Accuracy

Upper Temperature Control: ≤350°C to avoid the formation of harmful substances such as benzopyrene through thermal decomposition (e.g., IQOS is controlled below 320°C).

Heating Uniformity: Uneven heating can lead to localized overheating (producing harmful substances) or inadequate release (poor taste).

Precisely controlling the heating temperature maintains particle size within the 1-3μm range, balancing nicotine and aroma release, and improving the release efficiency of nicotine and flavor components.

2. Tobacco Medium Substrate Design

Reconstituted Tobacco: Optimize porosity and thermal conductivity.

Non-tobacco-Based Materials: Herbal or tea-based materials adjust the moisture and volatile matter ratio.

Optimizing the porosity and thermal conductivity of the tobacco matrix can improve the release efficiency of nicotine and flavor components while reducing the generation of harmful substances. The use of non-tobacco-based materials can provide HNB products with diverse flavors and tastes.

3. Functional Additives

Flavor Compensation: Compensate for the strengths and weaknesses of the substrate to enhance flavor characteristics.

Smoking Agent Ratio: By adjusting the PG/VG ratio, the viscosity and density of the aerosol can be controlled, improving nicotine delivery efficiency and taste.

Acid-base regulators: Organic acids are added to adjust the pH, control the ratio of nicotine to free base, and influence physiological potency and absorption rate.

Source: Yunnan Yidao Technology Co., Ltd. Presentation materials, excerpt

Recommended Activities

The 6th Atomizer Industry Chain Exhibition (August 26-28, Shenzhen)

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.