1. Inkjet Technology Application and Process

IJP is the abbreviation of Inkjet Printing, which is a digitally driven surface treatment printing technology that can convert graphic information into pulse electrical signals and transmit them to the inkjet head. The ink droplets (Ф0.02mm) are controlled by the nozzle to spray onto the surface of the substrate, and specific images or texts are printed at specific locations.

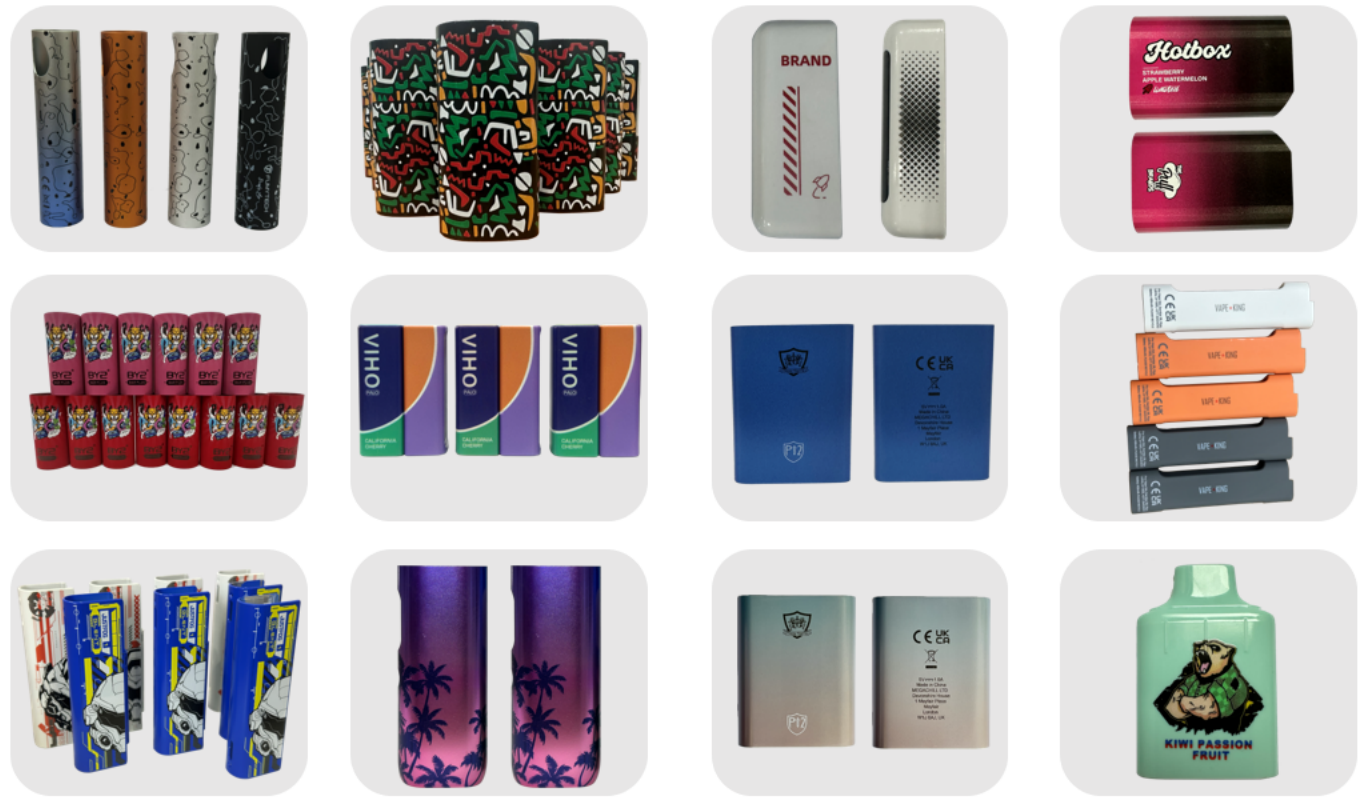

Technical application: 3D glass window inkjet, high-precision graphic printing or coating processing on non-planar or flat surfaces of various materials, can replace screen printing, pad printing, transfer printing, roller coating, spraying, coating, masking, film pasting, packaging, exposure and development, etc., with the advantages of high material utilization rate, good film thickness uniformity, low comprehensive cost, high production efficiency, safety and environmental protection.

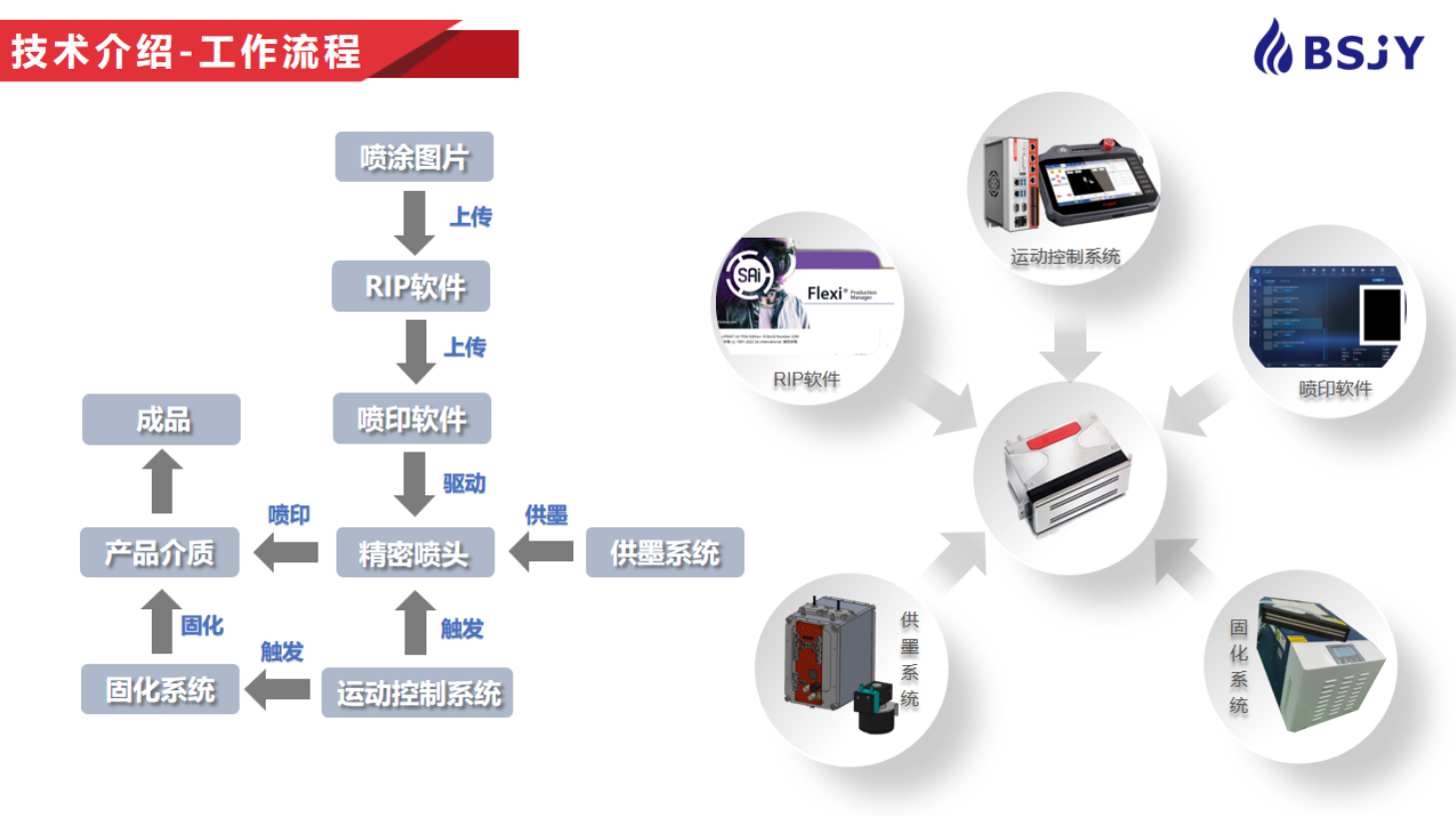

Workflow:

图源自 毕昇精一演讲PPT

2. Three core technology systems

- Graphics transfer technology core algorithm

Corresponding algorithms are developed based on requirements such as graphics, color, waveform resolution, flow, accuracy, thickness, etc. to provide precise command control of precision nozzles and equipment mechanisms.

- Innovative technology

New coating process technology that creates patterns using thousands of tiny ink droplets

- New material development

Research and develop new nano-scale polymer materials suitable for micro-aperture injection to meet the requirements of new processes for surface treatment, pattern coating and transfer of various materials.

3. Technical advantages

- High security

It uses micro-voltage printing, operates in the air, does not touch the product, and has no extrusion or friction. - High utilization rate of consumables

Ink is dispensed on demand, with no waste and high utilization rate of consumables. - High environmental protection level

The material is 100% high solid content, solvent-free, non-volatile, and produces no toxic substances, and the process is more environmentally friendly. - High finished product yield

The product consistency is good and the finished product yield is high. - No plate making requiredNo need for manual plate making, reduced preliminary processes, short product production cycle, high plate changing efficiency and low power consumption.

- Wide applicability

The printing software combined with the five-axis linkage of the equipment can realize 360° rotating contour printing, and the product has a wide range of applicability.

图源自 毕昇精一演讲PPT

图源自 毕昇精一演讲PPTAs a technological innovation in the field of surface treatment, the IJP process provides the e-cigarette industry with a transformation path from "manufacturing" to "intelligent manufacturing". Its technological value is not only reflected in the improvement of process efficiency, but also promotes the comprehensive upgrade of product design freedom and environmental protection standards.

Source: 艾邦根据毕昇精一演讲PPT整理

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.