Veteran e-cigarette users will likely relate to the images above. Previously, the standard solution for e-cigarette leakage was a simple three-step process: shake, puff, and wipe.

Leakage is a major deterrent for many new e-cigarette users. The pain of getting a puff of liquid in your mouth is truly unbearable, leading many interested e-cigarette users to give up after their initial attempts.

To address this issue, e-cigarette developers and product designers have racked their brains to devise numerous solutions. After years of effort, significant improvements have been made in both small-capacity transparent tanks and large-capacity models with reservoirs. With the exception of certain special circumstances, the "puff of liquid" problem is virtually eliminated.

However, leakage remains a serious issue for popular large-volume, transparent tank vapes on the market. Many companies' designs for large-volume, transparent tank vapes suffer from severe leaks: some leak before they're even opened, some leak after being a third of the way used, and some leak after being more than halfway used. Regardless of when a leak occurs, it creates a negative user experience. Furthermore, for large-volume vapes, leaks reduce e-liquid utilization and result in significant waste. Users may throw away a vape before using half the vape, ultimately refraining from purchasing that brand again. Therefore, addressing leaks is a crucial issue for large-volume, transparent tank vapes.

So, what exactly causes e-cigarette product leakage? Can it be solved scientifically?

E-cigarette leakage involves a multidisciplinary approach involving materials science, fluid mechanics, thermodynamics, and structural design. The following provides an in-depth analysis from a scientific perspective:

I. Structural Design and Material Property Deficiencies

1. Surface Tension Failure

E-cigarette liquid is primarily composed of a mixture of propylene glycol (PG), glycerin (VG), and nicotine. Its surface tension is significantly affected by temperature. When the atomizer heats unevenly, localized high temperatures reduce the liquid's surface tension, causing the liquid to leak through the seal. Therefore, if the seal design is not compatible with liquids of varying viscosities, continuous puffs, which increase the liquid temperature, can lead to leakage from the seal.

2. Microporous Effect

Atomizer cores are often made of porous ceramic or cotton fiber, with pore diameters ranging from approximately 10-50μm. If the porosity is too high or the pore size distribution is uneven, negative pressure inhalation can lead to an unbalanced capillary effect, allowing the smoke to penetrate the core directly into the airway. The porous structure of ceramic heating elements is unevenly distributed; some pores are very small, resulting in poor oil conduction, while others are large, resulting in insufficient oil retention and leaks.

II. Physical Mechanism

1. Pressure Difference Effect

According to the Bernoulli equation, a pressure differential of approximately 500-1000 Pa is generated between the inside and outside of the atomizer chamber when a user draws. When the seal ages (hardness exceeding 70° Shore A may result in failure) or when the assembly tolerance exceeds 0.1mm, the combined effects of this pressure differential and capillary forces can cause e-liquid to seep through the gaps, resulting in leakage. This problem is particularly prone to sudden puffs.

2. Thermal Expansion Effect

The volume expansion coefficient of e-liquid is approximately 0.0007/°C. The temperature difference between operating temperature (200-280°C) and room temperature (25°C) causes the volume expansion rate to reach 15.7%, exceeding the designed capacity of the liquid storage tank and causing overflow. Leakage caused by this expansion is generally not a significant issue during vaping. However, when the product is left in a high-temperature environment (such as a car in summer, where temperatures can reach over 60°C), the prolonged high temperature will cause the air inside the liquid tank and the structural components to expand. Over time, the combined effects of expansion pressure and capillary forces will cause the e-liquid to slowly leak out. Leakage from storage is currently a more difficult problem to address in e-cigarette products than leakage during vaping.

III. Chemical Factors

1. Influence of Solvent Polarity

The difference in polarity between propylene glycol (dielectric constant 32) and glycerin (dielectric constant 42.5) causes the mixture to tend to separate, especially after prolonged standing. The less polar component is more likely to penetrate the sealing material.

2. Additive Migration

Flavor molecules (such as menthol) have molecular weights between 150 and 300 Da, which can easily cause swelling reactions with silicone seals, reducing the contact angle from 110° to 80° and compromising sealing performance. In addition to the change in contact angle, the swelling of the silicone can also damage the seal, making it easier for e-liquid to leak through the seal failure area.

It‘s believed that many people who have used e-cigarettes have seen the phenomenon of silicone swelling, especially for transparent oil tank products. If an e-cigarette is not used for a long time, the silicone soaked in the oil will swell and grow larger, changing from white opaque to milky white translucent. This swelling will not only cause oil leakage problems, but also bring safety risks. The silicone used in e-cigarettes is not necessarily food-grade silicone. After swelling, substances will precipitate into the oil. This is one of the safety issues that need special attention and solution.

IV. User Behavior Induction

1. Puffing Dynamics

When consumers inhale deeply or puff hard, a significant negative pressure is generated in the e-cigarette's airway. This negative pressure can easily exceed the critical liquid lock pressure of the atomizer core (especially for cotton-core products). This can cause premature e-liquid to be drawn directly into the airway and then into the mouth along with the airflow. This is a type of puff leakage. This type of leakage during deep and hard puffs is caused by a mismatch between the atomizer core's liquid lock design and the negative pressure generated in the airway.

2. Impact of Mechanical Vibration

Consumers often play with e-cigarettes during daily use, even tapping them randomly and without direction. This sudden impact poses a significant risk to products with unstable structural designs. Structural instability can lead to seal failure under such sudden impacts, resulting in leakage. Furthermore, daily movement may cause random vibrations of varying frequencies, which can cause random fluctuations in the liquid level within the atomizer chamber. When the vibration amplitude exceeds a certain level, the impact of the e-liquid's own movement can also cause leakage. However, this is not the primary cause of leakage.

The above analysis shows that e-cigarette oil leakage is the result of the coupling of multiple factors. It is a multidisciplinary coupling problem involving fluid, heat transfer, structure and materials. To solve the problem of e-cigarette oil leakage, we must approach it from multiple aspects.

Source: Atomization Technology Innovation

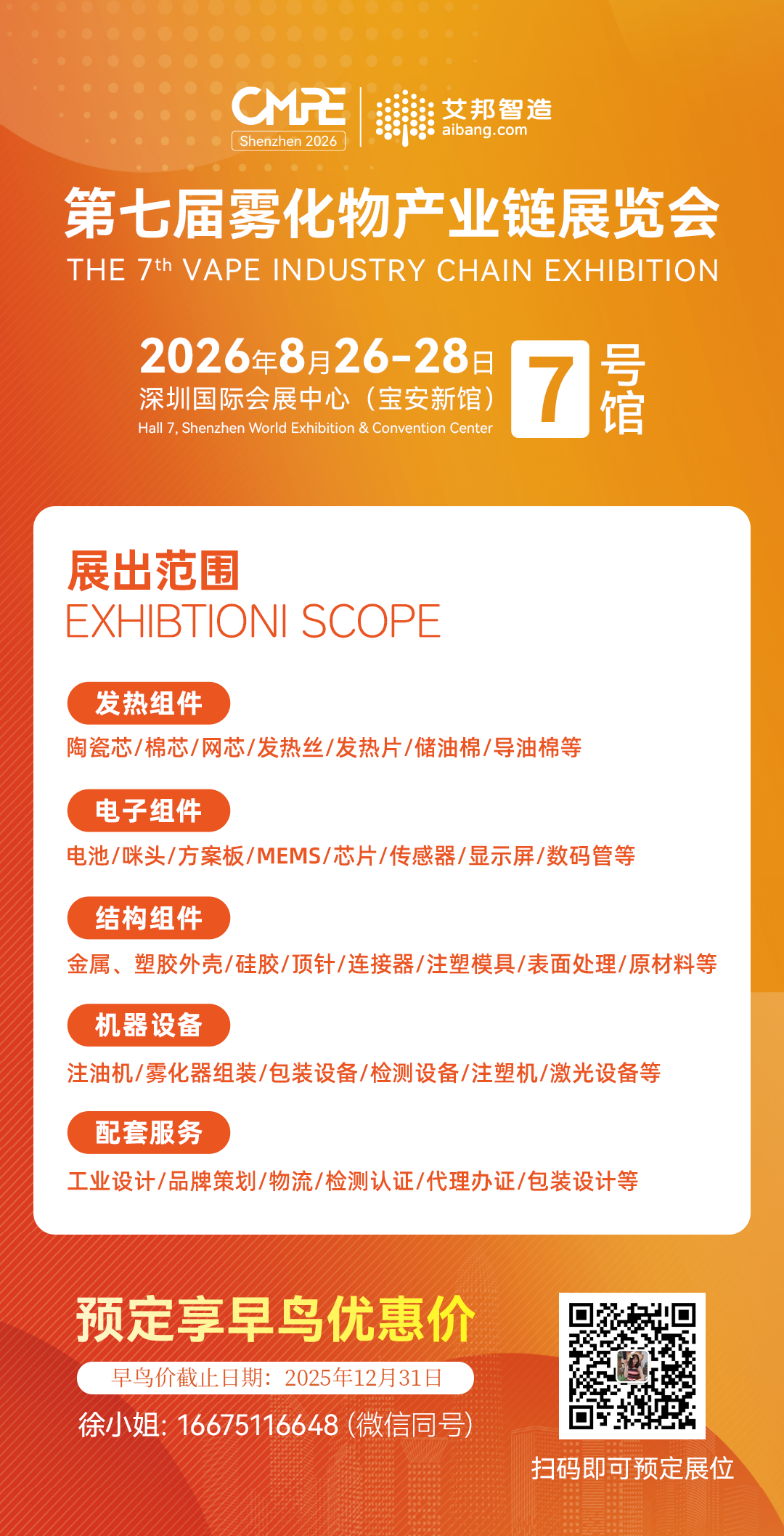

Electronic vaporization and HNB products are both new types of electronic devices. Although their structures are small, they integrate a variety of materials, surface treatment, chip electronics, and other technical processes. Moreover, the technology of atomization is constantly evolving, and the supply chain is gradually improving. In order to promote a good docking and communication among enterprises in the supply chain, Aibang has established an industrial WeChat group communication platform, which is open to everyone.

电子雾化与HNB产品都是新型电子产品,结构虽小,却融合应用多种材料、表面处理、芯片电子等技术工艺,而且雾化技术一直在不断更迭,供应链在逐步完善,为了促进供应链企业间有一个良好的对接交流,艾邦搭建产业微信群交流平台,欢迎加入;Vape e-cigarettes (VAPE) and Heat-Not-Burn e-cigarettes (HNB) are both emerging electronic products. Despite their compact size, they integrate various materials, surface treatment technologies, chip electronics, and other advanced technical processes. Moreover, atomization technology is constantly evolving and the supply chain is being progressively perfected. To facilitate good communication and networking among supply chain enterprises, Aibang has established an industry WeChat group communication platform and warmly welcomes interested enterprises to join.